Intro

Master inventory control with 5 expert tips, optimizing stock management, warehouse organization, and supply chain efficiency, reducing waste and boosting profitability through effective inventory tracking and analysis.

Effective inventory control is crucial for businesses to manage their stock levels, reduce costs, and improve customer satisfaction. Without a well-planned inventory control system, companies can face issues such as stockouts, overstocking, and wasted resources. In today's fast-paced business environment, it is essential to have a reliable inventory control system in place to stay competitive. In this article, we will discuss the importance of inventory control and provide valuable tips to help businesses optimize their inventory management.

Inventory control is a critical aspect of supply chain management that involves tracking and managing the flow of goods, products, and materials from raw materials to finished goods. It encompasses various activities, including inventory planning, procurement, storage, and distribution. A well-designed inventory control system helps businesses to minimize inventory costs, maximize inventory turnover, and ensure that products are available when customers need them. By implementing effective inventory control strategies, companies can improve their bottom line, enhance customer satisfaction, and gain a competitive edge in the market.

The benefits of inventory control are numerous, and it is essential for businesses to understand its importance to implement effective inventory management practices. Some of the key benefits of inventory control include reduced inventory costs, improved cash flow, increased customer satisfaction, and enhanced supply chain visibility. By controlling inventory levels, businesses can avoid overstocking and understocking, which can lead to wasted resources, lost sales, and damaged customer relationships. Moreover, effective inventory control enables companies to respond quickly to changes in demand, supply chain disruptions, and other market fluctuations.

Understanding Inventory Control

Inventory Control Techniques

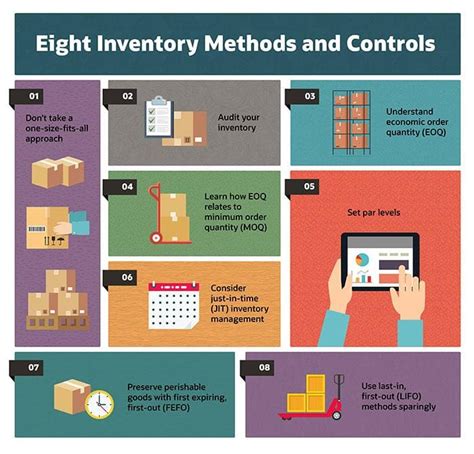

Inventory control techniques are methods used to manage and optimize inventory levels. Some common techniques include: * Just-in-time (JIT) inventory management: This technique involves ordering and receiving inventory just in time to meet customer demand. * Economic order quantity (EOQ): This technique involves calculating the optimal order quantity to minimize inventory costs. * Material requirements planning (MRP): This technique involves planning and scheduling inventory production to meet customer demand. * Inventory classification: This technique involves categorizing inventory into different classes based on their value, usage, and lead time.Inventory Control Tips

Benefits of Inventory Control

The benefits of inventory control are numerous, and businesses can experience significant improvements in their operations by implementing effective inventory management practices. Some of the key benefits of inventory control include: * Reduced inventory costs: Inventory control helps businesses to minimize inventory costs, including holding costs, ordering costs, and stockout costs. * Improved cash flow: By reducing inventory levels and minimizing inventory costs, businesses can improve their cash flow and enhance their financial performance. * Increased customer satisfaction: Inventory control ensures that products are available when customers need them, which can lead to increased customer satisfaction and loyalty. * Enhanced supply chain visibility: Inventory control provides businesses with real-time visibility into their supply chain, enabling them to respond quickly to changes in demand, supply chain disruptions, and other market fluctuations.Inventory Control Best Practices

Common Inventory Control Mistakes

Common inventory control mistakes can lead to significant problems, including stockouts, overstocking, and wasted resources. Some common inventory control mistakes include: * **Overreliance on Manual Inventory Management**: Manual inventory management can lead to errors, inaccuracies, and inefficiencies. * **Failure to Monitor and Analyze Inventory Levels**: Failure to monitor and analyze inventory levels can lead to stockouts, overstocking, and wasted resources. * **Inadequate Inventory Reporting and Analytics**: Inadequate inventory reporting and analytics can lead to poor decision-making and ineffective inventory management. * **Lack of Inventory Classification**: Lack of inventory classification can lead to inefficient inventory management and poor decision-making.Inventory Control Technology

Future of Inventory Control

The future of inventory control is exciting, with emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) expected to play a significant role in shaping the industry. Some potential trends and developments in inventory control include: * **Increased Use of Automation**: Automation is expected to play a significant role in inventory control, with businesses using robots, drones, and other automated systems to manage their inventory. * **Greater Use of Data Analytics**: Data analytics is expected to become increasingly important in inventory control, with businesses using data analytics to predict demand, optimize inventory levels, and reduce inventory costs. * **More Focus on Sustainability**: Sustainability is expected to become a major focus in inventory control, with businesses looking for ways to reduce their environmental impact and improve their sustainability.Gallery of Inventory Control

Inventory Control Image Gallery

Frequently Asked Questions

What is inventory control?

+Inventory control is the process of managing and regulating the flow of goods, products, and materials from raw materials to finished goods.

Why is inventory control important?

+Inventory control is important because it helps businesses to minimize inventory costs, maximize inventory turnover, and ensure that products are available when customers need them.

What are the benefits of inventory control?

+The benefits of inventory control include reduced inventory costs, improved cash flow, increased customer satisfaction, and enhanced supply chain visibility.

What are some common inventory control mistakes?

+Common inventory control mistakes include overreliance on manual inventory management, failure to monitor and analyze inventory levels, inadequate inventory reporting and analytics, and lack of inventory classification.

What is the future of inventory control?

+The future of inventory control is expected to be shaped by emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT), which will enable businesses to optimize their inventory management practices and improve their supply chain visibility.

In conclusion, inventory control is a critical aspect of supply chain management that helps businesses to manage their inventory levels, reduce costs, and improve customer satisfaction. By implementing effective inventory control strategies, companies can optimize their inventory management practices, improve their bottom line, and gain a competitive edge in the market. We hope that the information provided in this article has been helpful in understanding the importance of inventory control and the benefits it can bring to businesses. If you have any further questions or would like to share your experiences with inventory control, please feel free to comment below. Additionally, if you found this article informative, please share it with others who may benefit from it.