Intro

Boost efficiency with 5 ways to improve inventory turnover, optimizing stock management, and maximizing supply chain productivity through effective inventory control and logistics strategies.

The concept of inventory turnover is crucial for businesses, especially those in the retail and manufacturing sectors. It is a key performance indicator that measures the number of times inventory is sold and replaced within a given period. A high inventory turnover rate indicates that a company is selling its inventory quickly, which can lead to increased revenue and profitability. In this article, we will explore the importance of inventory turnover and provide 5 ways to improve it.

Inventory turnover is essential for businesses because it helps them to manage their inventory levels, reduce waste, and improve cash flow. When a company has a high inventory turnover rate, it means that it is selling its products quickly, which reduces the risk of inventory becoming obsolete or damaged. Additionally, a high inventory turnover rate can help a company to free up cash that is tied up in inventory, which can be used to invest in other areas of the business.

A low inventory turnover rate, on the other hand, can indicate that a company is holding too much inventory, which can lead to increased storage costs, waste, and obsolescence. It can also indicate that a company's products are not selling well, which can be a sign of a larger problem. Therefore, it is essential for businesses to monitor their inventory turnover rates and take steps to improve them.

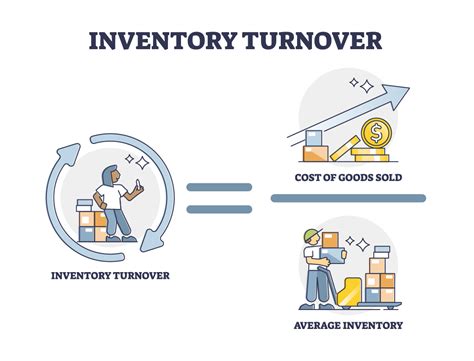

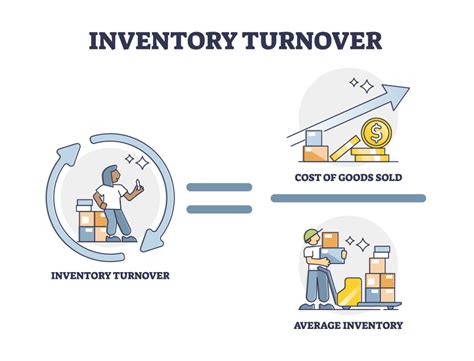

Understanding Inventory Turnover

Inventory turnover is calculated by dividing the cost of goods sold by the average inventory level. The formula for calculating inventory turnover is: Inventory Turnover = Cost of Goods Sold / Average Inventory. For example, if a company has a cost of goods sold of $100,000 and an average inventory level of $20,000, its inventory turnover rate would be 5. This means that the company is selling and replacing its inventory 5 times per year.

Benefits of High Inventory Turnover

A high inventory turnover rate has several benefits for businesses. Some of the benefits include: * Increased revenue and profitability * Reduced waste and obsolescence * Improved cash flow * Better inventory management * Increased efficiency and productivity5 Ways to Improve Inventory Turnover

Improving inventory turnover requires a combination of strategies that focus on managing inventory levels, reducing waste, and increasing sales. Here are 5 ways to improve inventory turnover:

- Optimize Inventory Levels: One of the most effective ways to improve inventory turnover is to optimize inventory levels. This involves analyzing sales data and adjusting inventory levels accordingly. Businesses can use inventory management software to track inventory levels and receive alerts when inventory needs to be replenished.

- Implement a Just-in-Time (JIT) Inventory System: A JIT inventory system involves ordering and receiving inventory just in time to meet customer demand. This approach helps to reduce inventory levels and minimize waste.

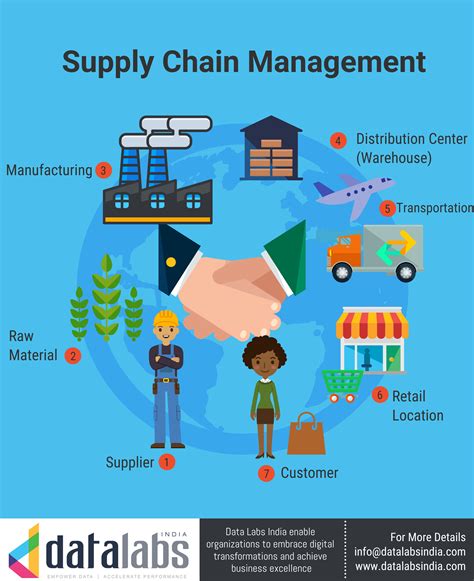

- Improve Supply Chain Management: Supply chain management is critical to inventory turnover. Businesses can improve supply chain management by working closely with suppliers, using transportation management systems, and implementing warehouse management systems.

- Use Data Analytics: Data analytics can help businesses to improve inventory turnover by providing insights into sales trends, customer behavior, and inventory levels. Businesses can use data analytics to identify areas for improvement and make data-driven decisions.

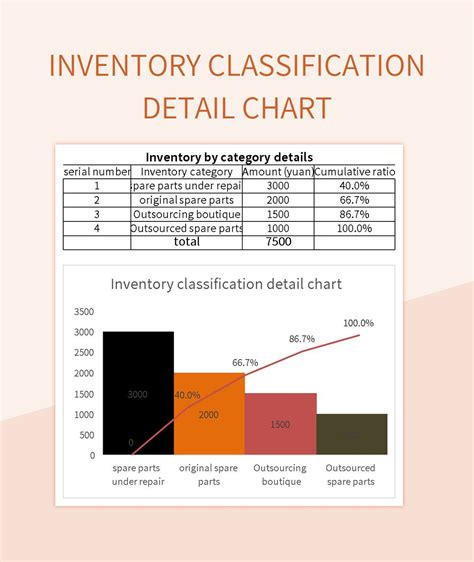

- Implement a Inventory Classification System: An inventory classification system involves categorizing inventory into different classes based on factors such as sales volume, profit margin, and inventory levels. This approach helps businesses to prioritize inventory management efforts and focus on high-value inventory items.

Best Practices for Inventory Management

In addition to the strategies mentioned above, there are several best practices that businesses can follow to improve inventory management and increase inventory turnover. Some of these best practices include: * Conducting regular inventory audits * Implementing a first-in, first-out (FIFO) inventory system * Using inventory management software * Providing training to inventory management staff * Continuously monitoring and evaluating inventory management processesCommon Mistakes to Avoid

When it comes to inventory management and inventory turnover, there are several common mistakes that businesses can make. Some of these mistakes include:

- Overstocking or understocking inventory

- Failing to monitor inventory levels

- Not implementing a inventory classification system

- Not providing training to inventory management staff

- Not continuously monitoring and evaluating inventory management processes

Industry Examples

Several industries have implemented successful inventory management strategies to improve inventory turnover. For example: * The retail industry has implemented JIT inventory systems to reduce inventory levels and minimize waste. * The manufacturing industry has implemented inventory classification systems to prioritize inventory management efforts and focus on high-value inventory items. * The healthcare industry has implemented inventory management software to track inventory levels and receive alerts when inventory needs to be replenished.Conclusion and Future Directions

In conclusion, inventory turnover is a critical metric for businesses, and improving it requires a combination of strategies that focus on managing inventory levels, reducing waste, and increasing sales. By optimizing inventory levels, implementing a JIT inventory system, improving supply chain management, using data analytics, and implementing a inventory classification system, businesses can improve inventory turnover and increase revenue and profitability.

As businesses continue to evolve and grow, it is essential to stay up-to-date with the latest trends and best practices in inventory management. Some future directions for inventory management include the use of artificial intelligence and machine learning to predict demand and optimize inventory levels, the implementation of blockchain technology to improve supply chain management, and the use of internet of things (IoT) devices to track inventory levels and receive alerts when inventory needs to be replenished.

Gallery of Inventory Turnover

Inventory Turnover Image Gallery

What is inventory turnover?

+Inventory turnover is a metric that measures the number of times inventory is sold and replaced within a given period.

Why is inventory turnover important?

+Inventory turnover is important because it helps businesses to manage their inventory levels, reduce waste, and improve cash flow.

How can I improve inventory turnover?

+You can improve inventory turnover by optimizing inventory levels, implementing a JIT inventory system, improving supply chain management, using data analytics, and implementing a inventory classification system.

What are the benefits of high inventory turnover?

+The benefits of high inventory turnover include increased revenue and profitability, reduced waste and obsolescence, improved cash flow, better inventory management, and increased efficiency and productivity.

How can I calculate inventory turnover?

+Inventory turnover can be calculated by dividing the cost of goods sold by the average inventory level.

We hope this article has provided you with a comprehensive understanding of inventory turnover and how to improve it. If you have any further questions or would like to share your experiences with inventory management, please leave a comment below. Additionally, if you found this article helpful, please share it with your colleagues and friends. We would also appreciate any feedback you may have on how we can improve our content to better serve your needs. Thank you for reading!