Intro

Discover innovative 3D printable turntable designs, featuring rotating platforms, modular parts, and customizable models, perfect for music enthusiasts and makers seeking unique DIY projects with precision rotation and aesthetic appeal.

The world of 3D printing has revolutionized the way we create and design objects, allowing for unprecedented levels of customization and precision. One area where 3D printing has made a significant impact is in the creation of turntable designs. For music enthusiasts and audiophiles, a high-quality turntable is essential for enjoying their favorite records. With 3D printing, it's now possible to create custom turntable designs that are both functional and visually stunning. In this article, we'll explore the world of 3D printable turntable designs, their benefits, and what you need to know to get started.

The importance of turntable design cannot be overstated. A well-designed turntable can make all the difference in the sound quality and overall listening experience. With 3D printing, designers can create complex geometries and custom shapes that would be impossible to produce with traditional manufacturing methods. This has led to a proliferation of innovative and unique turntable designs that are both functional and aesthetically pleasing. Whether you're a seasoned audiophile or just starting to build your record collection, a 3D printed turntable design can be a great way to enhance your listening experience.

For those new to 3D printing, the concept of creating a custom turntable design may seem daunting. However, with the right tools and knowledge, it's easier than you think. There are many online resources and communities dedicated to 3D printing and turntable design, where you can find inspiration, tutorials, and guidance. Additionally, many 3D printing companies offer pre-designed turntable models that can be customized to your specifications. With the rise of affordable 3D printing technology, it's now possible for anyone to create their own custom turntable design.

Benefits of 3D Printable Turntable Designs

One of the primary benefits of 3D printable turntable designs is their customizability. With 3D printing, you can create a turntable that meets your specific needs and preferences. Whether you're looking for a specific color, shape, or material, 3D printing makes it possible. Additionally, 3D printed turntables can be designed with specific features and functionalities in mind, such as built-in amplifiers or USB connectivity. This level of customization is unparalleled in traditional turntable manufacturing, where designs are often limited by production costs and manufacturing constraints.

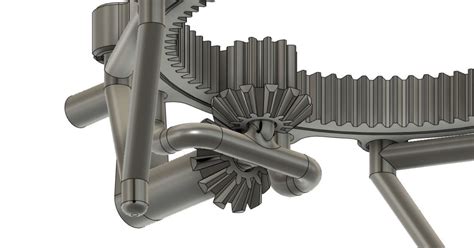

Another benefit of 3D printable turntable designs is their potential for innovation. With 3D printing, designers can experiment with new materials, shapes, and geometries that would be impossible to produce with traditional methods. This has led to the development of novel turntable designs that combine function and aesthetics in unique and creative ways. For example, some 3D printed turntables feature intricate designs and patterns that not only look stunning but also provide improved sound quality. Others incorporate advanced technologies, such as wireless connectivity or automated record cleaning systems.

How 3D Printable Turntable Designs Work

So, how do 3D printable turntable designs work? The process begins with design, where a 3D model of the turntable is created using specialized software. This model is then sliced into thin layers, which are printed layer by layer using a 3D printer. The printing process can take several hours or even days, depending on the complexity of the design and the capabilities of the printer. Once the printing is complete, the turntable is assembled and tested to ensure that it meets the desired specifications.

One of the key components of a 3D printed turntable is the platter, which is the rotating disc that holds the record. The platter is typically made from a high-density material, such as aluminum or stainless steel, which provides a smooth and stable surface for the record to rotate on. The platter is then attached to a bearing, which allows it to rotate smoothly and quietly. The bearing is typically made from a high-quality material, such as ceramic or bronze, which provides a low-friction surface for the platter to rotate on.

Steps to Create a 3D Printable Turntable Design

Creating a 3D printable turntable design requires several steps, including:

- Design: Create a 3D model of the turntable using specialized software.

- Slicing: Slice the 3D model into thin layers, which will be printed layer by layer.

- Printing: Print the layers using a 3D printer.

- Assembly: Assemble the printed parts and attach the platter and bearing.

- Testing: Test the turntable to ensure that it meets the desired specifications.

Types of 3D Printable Turntable Designs

There are several types of 3D printable turntable designs available, each with its own unique features and benefits. Some popular types include:

- Belt-driven turntables: These turntables use a belt to drive the platter, which provides a smooth and quiet rotation.

- Direct-drive turntables: These turntables use a direct-drive motor to rotate the platter, which provides a high-torque and stable rotation.

- Idler-wheel turntables: These turntables use an idler wheel to drive the platter, which provides a smooth and quiet rotation.

Each type of turntable has its own advantages and disadvantages, and the choice of which one to use will depend on your specific needs and preferences. For example, belt-driven turntables are known for their smooth and quiet operation, but may require more maintenance than direct-drive turntables. Direct-drive turntables, on the other hand, are known for their high-torque and stable rotation, but may be more expensive than belt-driven turntables.

Materials Used in 3D Printable Turntable Designs

The materials used in 3D printable turntable designs can vary depending on the specific application and desired properties. Some common materials used include:

- PLA (polylactic acid): A biodegradable and renewable material that is easy to print with and provides a smooth finish.

- ABS (acrylonitrile butadiene styrene): A strong and impact-resistant material that is commonly used in 3D printing.

- PETG (polyethylene terephthalate glycol): A strong and flexible material that is resistant to warping and provides a smooth finish.

Each material has its own advantages and disadvantages, and the choice of which one to use will depend on your specific needs and preferences. For example, PLA is a good choice for turntables that require a smooth finish and are not subject to high stresses, while ABS is a good choice for turntables that require high strength and impact resistance.

Advantages and Disadvantages of 3D Printable Turntable Designs

Like any technology, 3D printable turntable designs have their advantages and disadvantages. One of the main advantages is their customizability, which allows users to create turntables that meet their specific needs and preferences. Another advantage is their potential for innovation, which has led to the development of novel turntable designs that combine function and aesthetics in unique and creative ways.

However, 3D printable turntable designs also have some disadvantages. One of the main disadvantages is their cost, which can be higher than traditional turntables. Another disadvantage is their complexity, which can make them more difficult to assemble and maintain. Additionally, 3D printed turntables may not provide the same level of sound quality as traditional turntables, although this can depend on the specific design and materials used.

Common Applications of 3D Printable Turntable Designs

3D printable turntable designs have a wide range of applications, including:

- Home audio systems: 3D printed turntables can be used in home audio systems to provide a unique and customized listening experience.

- Professional audio systems: 3D printed turntables can be used in professional audio systems, such as recording studios and live sound systems.

- DJ equipment: 3D printed turntables can be used in DJ equipment, such as turntables and mixers.

Each application has its own specific requirements and challenges, and the choice of which type of turntable to use will depend on your specific needs and preferences. For example, home audio systems may require a turntable with a smooth and quiet operation, while professional audio systems may require a turntable with high-torque and stable rotation.

Future of 3D Printable Turntable Designs

The future of 3D printable turntable designs is exciting and full of possibilities. As 3D printing technology continues to advance, we can expect to see even more innovative and complex turntable designs. One area of development is in the use of new materials and technologies, such as carbon fiber and nanomaterials, which can provide improved strength, stiffness, and sound quality.

Another area of development is in the integration of advanced technologies, such as wireless connectivity and automated record cleaning systems. These technologies can provide a more convenient and user-friendly experience, and can also improve the sound quality and overall performance of the turntable.

Challenges and Limitations of 3D Printable Turntable Designs

Despite the many advantages and possibilities of 3D printable turntable designs, there are also some challenges and limitations to consider. One of the main challenges is the cost, which can be higher than traditional turntables. Another challenge is the complexity, which can make them more difficult to assemble and maintain.

Additionally, 3D printed turntables may not provide the same level of sound quality as traditional turntables, although this can depend on the specific design and materials used. Furthermore, the use of 3D printing technology can also raise questions about the durability and longevity of the turntable, as well as the potential for maintenance and repair.

3D Printable Turntable Designs Image Gallery

What is 3D printing and how does it work?

+3D printing is a manufacturing process that creates objects layer by layer using a digital model. It works by depositing material, such as plastic or metal, onto a build platform, where it is fused together to form the final product.

What are the benefits of 3D printable turntable designs?

+The benefits of 3D printable turntable designs include customizability, innovation, and improved sound quality. They can be designed to meet specific needs and preferences, and can incorporate advanced technologies and materials.

What are the challenges and limitations of 3D printable turntable designs?

+The challenges and limitations of 3D printable turntable designs include cost, complexity, and potential durability and longevity issues. They may also require specialized knowledge and equipment to assemble and maintain.

In summary, 3D printable turntable designs offer a unique and innovative way to create custom turntables that meet specific needs and preferences. With their customizability, potential for innovation, and improved sound quality, they are an exciting development in the world of audio technology. While they may have some challenges and limitations, they offer a wide range of possibilities for music enthusiasts and audiophiles. Whether you're looking to create a custom turntable for your home audio system or professional audio setup, 3D printable turntable designs are definitely worth considering. We invite you to share your thoughts and experiences with 3D printable turntable designs in the comments below, and to explore the many resources and communities available online for more information and inspiration.