Intro

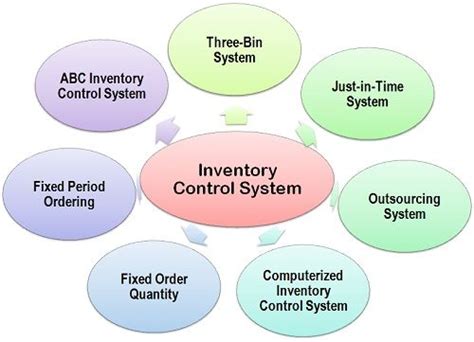

Discover the 5 Ways Inventory Formula to optimize stock levels, reduce waste, and boost profitability with effective inventory management techniques, including demand forecasting, supply chain optimization, and inventory control methods.

The importance of inventory management cannot be overstated, as it plays a crucial role in the success of businesses, particularly those in the retail and manufacturing sectors. Effective inventory management helps companies to maintain the right amount of stock, minimize waste, and maximize profits. One key aspect of inventory management is the use of inventory formulas, which enable businesses to calculate and optimize their inventory levels. In this article, we will delve into the world of inventory formulas, exploring five essential formulas that can help businesses to streamline their inventory management processes.

Inventory management is a complex process that involves balancing the need to meet customer demand with the need to minimize inventory costs. If a business has too much inventory, it can lead to waste and unnecessary expenses, while having too little inventory can result in lost sales and damaged customer relationships. By using inventory formulas, businesses can make informed decisions about their inventory levels, ensuring that they have the right amount of stock to meet customer demand while minimizing waste and costs.

The use of inventory formulas is not limited to large businesses; small and medium-sized enterprises can also benefit from using these formulas to optimize their inventory management. By applying these formulas, businesses can identify areas for improvement, reduce inventory costs, and improve their overall efficiency. In the following sections, we will explore five essential inventory formulas, including the Economic Order Quantity (EOQ) formula, the Reorder Point (ROP) formula, the Inventory Turnover formula, the Service Level formula, and the Fill Rate formula.

Introduction to Inventory Formulas

Inventory formulas are mathematical equations that help businesses to calculate and optimize their inventory levels. These formulas take into account various factors, such as demand, lead time, and inventory costs, to provide businesses with accurate and reliable data. By using inventory formulas, businesses can make informed decisions about their inventory management, reducing the risk of stockouts, overstocking, and waste.

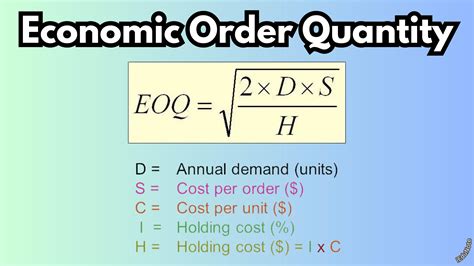

Economic Order Quantity (EOQ) Formula

The Economic Order Quantity (EOQ) formula is a widely used inventory formula that helps businesses to determine the optimal order quantity for their inventory. The formula takes into account the demand for the product, the cost of ordering and holding inventory, and the lead time for delivery. The EOQ formula is calculated as follows:

EOQ = √(2DS/H)

Where: D = Demand for the product S = Cost of ordering H = Cost of holding inventory

The EOQ formula helps businesses to minimize their inventory costs by determining the optimal order quantity that balances the cost of ordering and holding inventory.

Reorder Point (ROP) Formula

The Reorder Point (ROP) formula is another essential inventory formula that helps businesses to determine when to reorder their inventory. The formula takes into account the lead time for delivery, the demand for the product, and the safety stock level. The ROP formula is calculated as follows:

ROP = (Lead Time x Demand) + Safety Stock

Where: Lead Time = Time it takes for the inventory to arrive Demand = Demand for the product Safety Stock = Minimum amount of inventory required to meet customer demand

The ROP formula helps businesses to avoid stockouts by determining the optimal time to reorder their inventory.

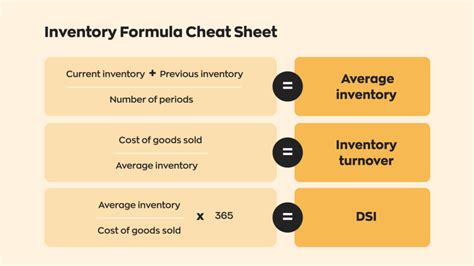

Inventory Turnover Formula

The Inventory Turnover formula is a key performance indicator (KPI) that helps businesses to measure their inventory efficiency. The formula calculates the number of times inventory is sold and replaced within a given period. The Inventory Turnover formula is calculated as follows:

Inventory Turnover = Cost of Goods Sold / Average Inventory

Where: Cost of Goods Sold = Total cost of goods sold Average Inventory = Average inventory level over a given period

The Inventory Turnover formula helps businesses to identify areas for improvement in their inventory management, such as reducing inventory costs and improving inventory turnover.

Service Level Formula

The Service Level formula is an essential inventory formula that helps businesses to measure their ability to meet customer demand. The formula calculates the percentage of customer demand that is met from existing inventory. The Service Level formula is calculated as follows:

Service Level = (Demand Met / Total Demand) x 100

Where: Demand Met = Demand met from existing inventory Total Demand = Total customer demand

The Service Level formula helps businesses to identify areas for improvement in their inventory management, such as improving their service level and reducing stockouts.

Fill Rate Formula

The Fill Rate formula is another key performance indicator (KPI) that helps businesses to measure their inventory efficiency. The formula calculates the percentage of customer orders that are filled from existing inventory. The Fill Rate formula is calculated as follows:

Fill Rate = (Orders Filled / Total Orders) x 100

Where: Orders Filled = Orders filled from existing inventory Total Orders = Total customer orders

The Fill Rate formula helps businesses to identify areas for improvement in their inventory management, such as improving their fill rate and reducing stockouts.

Gallery of Inventory Management

Inventory Management Image Gallery

What is the purpose of inventory management?

+The purpose of inventory management is to ensure that a business has the right amount of inventory to meet customer demand while minimizing waste and costs.

What are the benefits of using inventory formulas?

+The benefits of using inventory formulas include improved inventory management, reduced waste and costs, and increased efficiency.

How can businesses implement inventory management best practices?

+Businesses can implement inventory management best practices by using inventory formulas, optimizing their inventory levels, and improving their inventory turnover.

What is the importance of inventory turnover?

+Inventory turnover is an important metric that helps businesses to measure their inventory efficiency and identify areas for improvement.

How can businesses improve their service level?

+Businesses can improve their service level by optimizing their inventory levels, improving their inventory turnover, and reducing stockouts.

In conclusion, inventory formulas are essential tools that can help businesses to optimize their inventory management. By using these formulas, businesses can improve their inventory efficiency, reduce waste and costs, and increase their profitability. We encourage readers to share their experiences and tips on inventory management in the comments section below. Additionally, we invite readers to share this article with their colleagues and friends who may benefit from learning about inventory formulas. By working together, we can improve our inventory management skills and achieve greater success in our businesses.