Intro

Discover what is Stock Keeping Unit (SKU) and its importance in inventory management, product tracking, and supply chain optimization, using unique identifiers and barcode scanning for efficient stock control and retail operations.

The concept of a Stock Keeping Unit, commonly referred to as an SKU, is fundamental in the realm of inventory management and retail. It serves as a unique identifier for each product or service offered by a company, enabling efficient tracking, management, and control of inventory levels. In essence, an SKU is a distinct code assigned to a specific product or item, distinguishing it from other products within the same inventory. This unique identifier is crucial for businesses, as it facilitates accurate inventory management, streamlines supply chain operations, and enhances customer satisfaction.

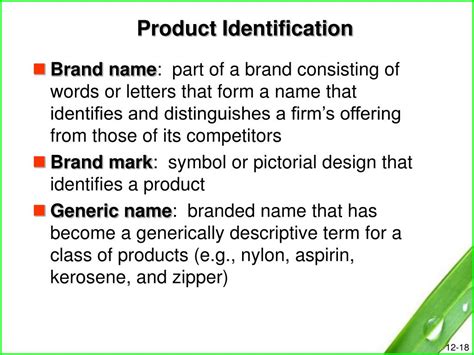

Understanding the importance of SKUs is vital for businesses aiming to optimize their inventory management processes. An SKU typically includes a combination of letters and numbers that provide detailed information about the product, such as its brand, model, size, color, and packaging. For instance, a company selling clothing might use an SKU like "SHIRT-RED-M" to identify a red, medium-sized shirt. This specificity allows for precise tracking of inventory levels, making it easier to manage stock, prevent overstocking or understocking, and ensure that the right products are available to meet customer demand.

Effective use of SKUs can have a significant impact on a company's bottom line. By accurately tracking inventory levels and movements, businesses can reduce costs associated with overstocking, such as storage and maintenance expenses. Moreover, SKUs help in minimizing stockouts, which can lead to lost sales and disappointed customers. The use of SKUs also enables businesses to analyze sales trends and product performance, making informed decisions about future inventory purchases and product offerings.

Benefits of Using Stock Keeping Units

The benefits of implementing SKUs in inventory management are multifaceted. Firstly, SKUs enhance inventory accuracy, allowing businesses to maintain up-to-date records of their stock levels. This accuracy is crucial for preventing inventory discrepancies and ensuring that customer orders are fulfilled correctly. Secondly, SKUs facilitate quicker inventory turns, as they enable businesses to identify fast-moving and slow-moving products. This insight helps in optimizing inventory levels, reducing the need for excess storage space, and improving cash flow.

Furthermore, SKUs play a vital role in streamlining supply chain operations. By using unique identifiers for each product, businesses can efficiently manage their supply chains, from procurement to delivery. SKUs also enable businesses to track product movements, monitor inventory levels across different locations, and automate inventory reporting. This level of visibility and control is essential for maintaining a competitive edge in today's fast-paced business environment.

How SKUs Work in Inventory Management

The implementation of SKUs in inventory management involves several key steps. Firstly, businesses must assign a unique SKU to each product or item in their inventory. This SKU should be descriptive, including details such as product name, size, color, and packaging. Once SKUs are assigned, businesses can use them to track inventory levels, monitor product movements, and analyze sales trends.To effectively use SKUs, businesses must also establish a robust inventory management system. This system should be capable of storing and processing SKU data, generating reports, and providing real-time updates on inventory levels. Many businesses opt for automated inventory management systems, which can integrate with point-of-sale systems, e-commerce platforms, and supply chain management software.

Best Practices for Implementing Stock Keeping Units

Implementing SKUs requires careful planning and execution. One of the best practices is to keep SKUs concise and descriptive, making it easier for employees and systems to understand and process them. Businesses should also establish a standardized format for their SKUs, ensuring consistency across all products and locations.

Another crucial practice is to regularly review and update SKUs. As product offerings change, SKUs must be adjusted to reflect these changes. This includes creating new SKUs for new products, merging SKUs for similar products, and discontinuing SKUs for discontinued products. Regular reviews also help in identifying and correcting any errors or discrepancies in SKU data, ensuring the accuracy and reliability of inventory records.

Common Challenges in Using Stock Keeping Units

Despite the benefits of SKUs, businesses may encounter several challenges when implementing and using them. One common challenge is the complexity of creating and managing SKUs, particularly for businesses with large and diverse product offerings. This complexity can lead to errors, inconsistencies, and confusion among employees and customers.Another challenge is the integration of SKUs with existing inventory management systems and supply chain operations. Businesses must ensure that their SKUs are compatible with their systems and processes, which can require significant investments in technology and training. Furthermore, the use of SKUs requires ongoing maintenance and updates, which can be time-consuming and resource-intensive.

Future of Stock Keeping Units in Inventory Management

The future of SKUs in inventory management is closely tied to advancements in technology and changes in consumer behavior. With the rise of e-commerce and omnichannel retailing, businesses must be able to manage their inventories across multiple channels and locations. SKUs will play a critical role in this process, enabling businesses to track inventory levels, monitor product movements, and fulfill customer orders efficiently.

The increasing use of artificial intelligence, machine learning, and data analytics will also impact the use of SKUs. These technologies will enable businesses to analyze SKU data more effectively, gaining insights into sales trends, product performance, and customer behavior. This information will help businesses make informed decisions about inventory management, product offerings, and supply chain operations, ultimately enhancing their competitiveness and profitability.

Real-World Applications of Stock Keeping Units

SKUs have numerous real-world applications across various industries. In retail, SKUs are used to manage inventory levels, track product sales, and optimize supply chain operations. In manufacturing, SKUs are used to identify and track components, manage production schedules, and control inventory levels.In the healthcare industry, SKUs are used to manage medical supplies, track inventory levels, and ensure compliance with regulatory requirements. In the food industry, SKUs are used to manage inventory levels, track product freshness, and ensure compliance with food safety regulations.

Stock Keeping Unit Image Gallery

Stock Keeping Unit Image Gallery

Frequently Asked Questions

What is a Stock Keeping Unit?

+A Stock Keeping Unit (SKU) is a unique identifier for each product or service offered by a company, enabling efficient tracking, management, and control of inventory levels.

Why are SKUs important in inventory management?

+SKUs are important because they enable businesses to accurately track inventory levels, monitor product movements, and analyze sales trends, ultimately enhancing their competitiveness and profitability.

How do businesses implement SKUs in their inventory management systems?

+Businesses implement SKUs by assigning a unique identifier to each product or item, establishing a robust inventory management system, and regularly reviewing and updating SKUs to reflect changes in product offerings.

What are the benefits of using SKUs in inventory management?

+The benefits of using SKUs include enhanced inventory accuracy, quicker inventory turns, streamlined supply chain operations, and improved decision-making through data analysis.

What are the common challenges in using SKUs, and how can businesses overcome them?

+Common challenges include complexity, integration with existing systems, and ongoing maintenance. Businesses can overcome these challenges by establishing standardized SKU formats, investing in technology and training, and regularly reviewing and updating SKUs.

In conclusion, Stock Keeping Units play a vital role in inventory management, enabling businesses to efficiently track, manage, and control their inventory levels. By understanding the importance of SKUs, implementing them effectively, and overcoming common challenges, businesses can enhance their competitiveness, improve customer satisfaction, and increase profitability. As the retail landscape continues to evolve, the use of SKUs will remain a critical component of successful inventory management strategies. We invite you to share your thoughts on the importance of SKUs in inventory management and how they have impacted your business operations. Your feedback and insights will help us better understand the complexities of inventory management and the role of SKUs in driving business success.