Intro

Discover 5 flange size tips for precise pipe fittings, including measurement guides, material considerations, and torque specifications to ensure leak-free connections and optimal performance in industrial piping systems.

When it comes to working with pipes and fittings, one of the most critical components is the flange. A flange is a type of fitting that is used to connect two pipes together, or to connect a pipe to a valve, pump, or other equipment. The size of the flange is crucial, as it determines the amount of fluid that can flow through the pipe, as well as the amount of pressure that the pipe can withstand. In this article, we will provide 5 flange size tips to help you choose the right size for your piping system.

Flanges come in a variety of sizes, ranging from small diameters of less than an inch to large diameters of several feet. The size of the flange is typically measured in terms of its nominal pipe size, which is the diameter of the pipe that the flange is designed to fit. The nominal pipe size is usually designated by a number, such as 1/2", 1", 2", etc. However, the actual diameter of the flange may be slightly larger or smaller than the nominal pipe size, depending on the specific design and manufacturer.

The importance of choosing the right flange size cannot be overstated. If the flange is too small, it can restrict the flow of fluid through the pipe, leading to reduced performance and efficiency. On the other hand, if the flange is too large, it can be difficult to handle and install, and may require additional support and reinforcement. Furthermore, an incorrectly sized flange can also lead to safety issues, such as leaks and ruptures, which can be catastrophic in certain applications.

Therefore, it is essential to carefully consider the size of the flange when designing and installing a piping system. In the following sections, we will provide more detailed information and tips on how to choose the right flange size for your specific application.

Understanding Flange Sizes

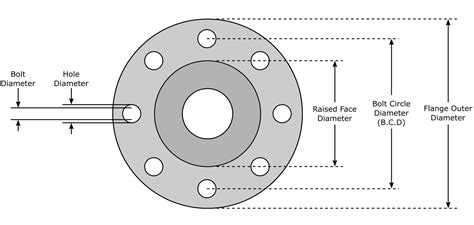

To choose the right flange size, you need to understand the different types of flange sizes and how they are measured. Flange sizes are typically designated by a combination of numbers and letters, which indicate the nominal pipe size, the pressure rating, and the material of the flange. For example, a flange size of "2" 150# RF" indicates that the flange has a nominal pipe size of 2 inches, a pressure rating of 150 pounds per square inch (PSI), and a raised face (RF) design.

It is also important to note that flange sizes can vary depending on the specific standard or specification being used. For example, the American Society of Mechanical Engineers (ASME) has its own set of standards for flange sizes, which may differ from those used by other organizations or countries.

Flange Size Standards

Some of the most common flange size standards include:

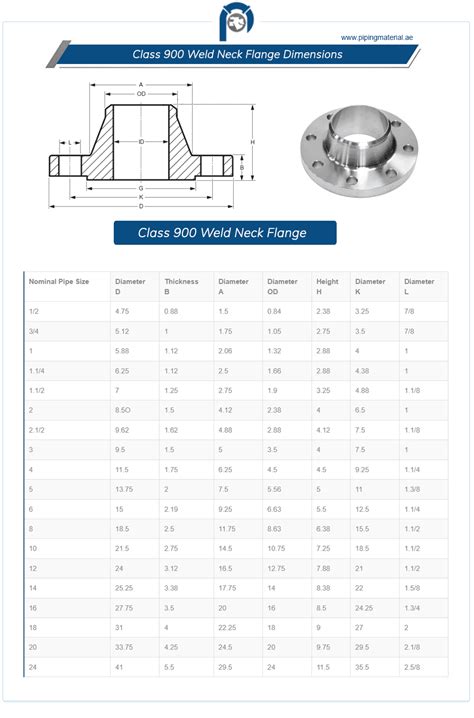

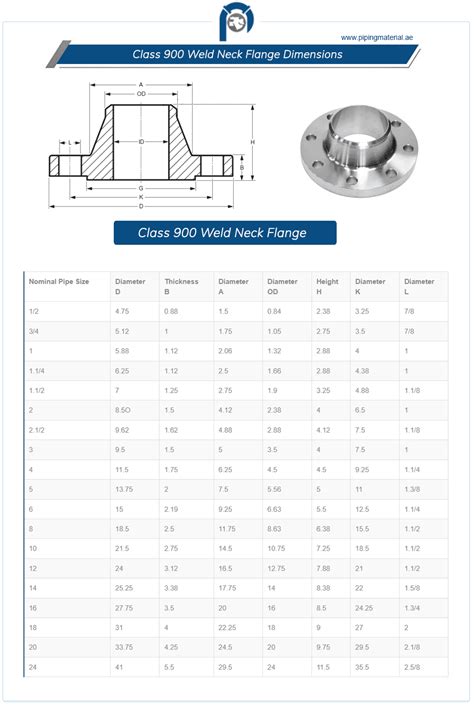

- ASME B16.5: This standard covers flanges with nominal pipe sizes ranging from 1/2" to 24".

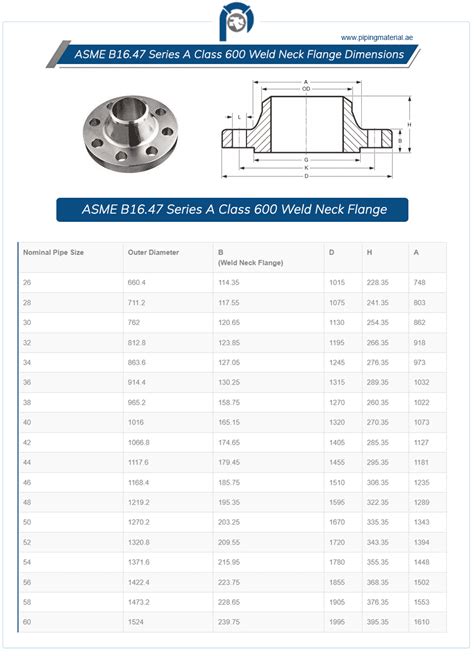

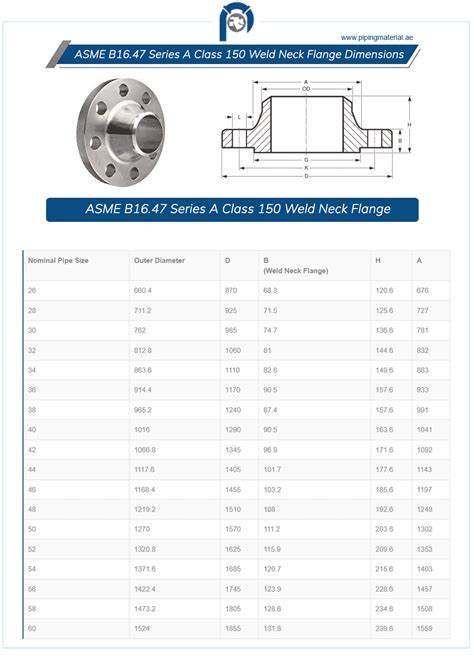

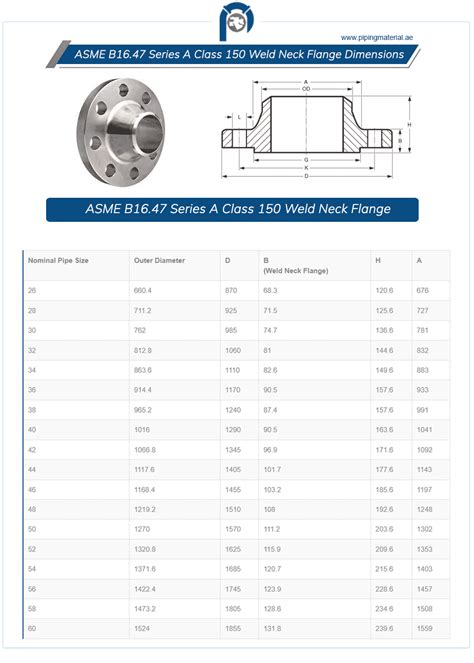

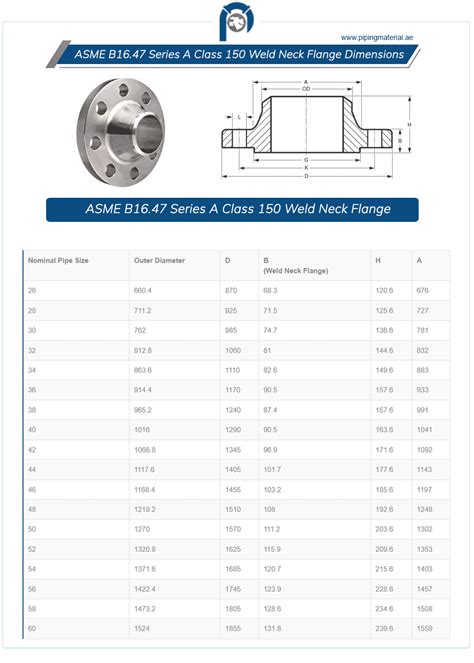

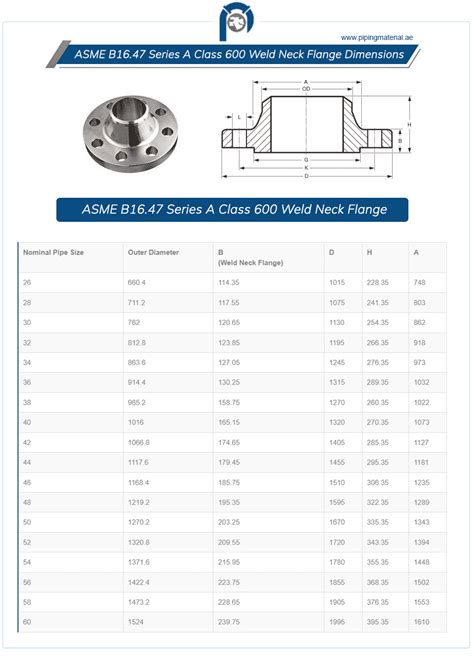

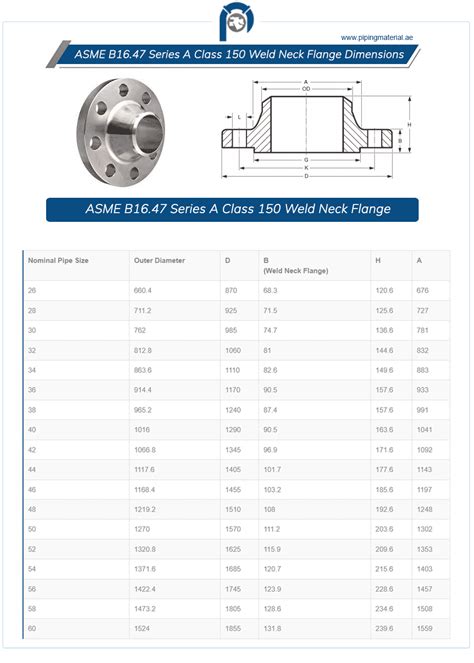

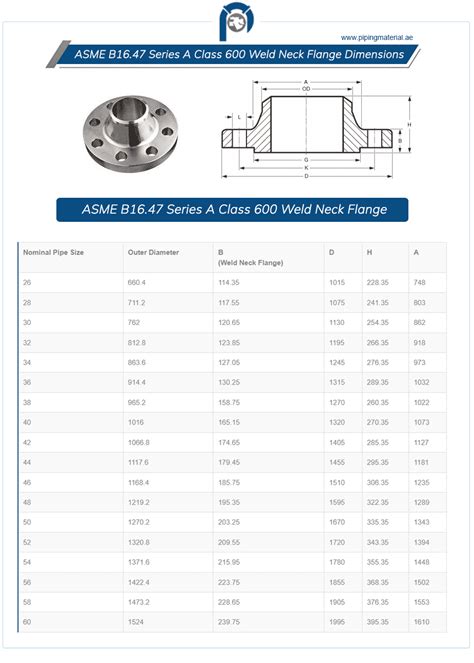

- ASME B16.47: This standard covers flanges with nominal pipe sizes ranging from 26" to 60".

- ISO 7005: This standard covers flanges with nominal pipe sizes ranging from DN 10 to DN 4000.

- DIN 2501: This standard covers flanges with nominal pipe sizes ranging from DN 10 to DN 3000.

Choosing the Right Flange Size

Choosing the right flange size involves several factors, including the nominal pipe size, the pressure rating, and the material of the flange. Here are some tips to help you choose the right flange size:

- Determine the nominal pipe size: The nominal pipe size is the most critical factor in choosing the right flange size. Make sure to select a flange that matches the nominal pipe size of your piping system.

- Consider the pressure rating: The pressure rating of the flange is also crucial, as it determines the maximum amount of pressure that the flange can withstand. Choose a flange with a pressure rating that meets or exceeds the maximum operating pressure of your piping system.

- Select the right material: The material of the flange is also important, as it affects the strength, durability, and corrosion resistance of the flange. Common materials used for flanges include carbon steel, stainless steel, and aluminum.

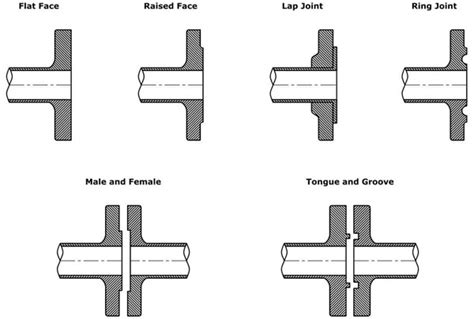

- Check the flange design: The design of the flange is also important, as it affects the ease of installation and maintenance. Common flange designs include raised face (RF), flat face (FF), and ring-type joint (RTJ).

- Consult the manufacturer's specifications: Finally, consult the manufacturer's specifications to ensure that the flange you choose meets all the necessary requirements and standards.

Flange Size Calculation

To calculate the flange size, you need to consider the following factors:

- Nominal pipe size

- Pressure rating

- Material of the flange

- Flange design

- Operating temperature and pressure

You can use the following formula to calculate the flange size: Flange size = (Nominal pipe size x Pressure rating) / (Material factor x Design factor)

Where:

- Material factor = 1 for carbon steel, 1.5 for stainless steel, and 2 for aluminum

- Design factor = 1 for raised face, 1.2 for flat face, and 1.5 for ring-type joint

Flange Size Tips and Tricks

Here are some additional tips and tricks to help you choose the right flange size:

- Always consult the manufacturer's specifications and recommendations.

- Use a flange size calculator or software to ensure accurate calculations.

- Consider the operating temperature and pressure of your piping system.

- Choose a flange with a pressure rating that meets or exceeds the maximum operating pressure.

- Select a flange with a material that is compatible with the fluid being transported.

Common Flange Size Mistakes

Some common mistakes to avoid when choosing a flange size include:

- Choosing a flange that is too small or too large for the piping system.

- Selecting a flange with an incorrect pressure rating or material.

- Failing to consult the manufacturer's specifications and recommendations.

- Not considering the operating temperature and pressure of the piping system.

Flange Size Applications

Flanges are used in a wide range of applications, including:

- Oil and gas pipelines

- Chemical processing plants

- Power generation plants

- Water treatment plants

- Industrial piping systems

In each of these applications, the flange size plays a critical role in ensuring the safe and efficient operation of the piping system.

Flange Size Selection for Specific Applications

Here are some tips for selecting the right flange size for specific applications:

- Oil and gas pipelines: Choose a flange with a high pressure rating and a material that is resistant to corrosion.

- Chemical processing plants: Select a flange with a material that is compatible with the chemicals being processed.

- Power generation plants: Choose a flange with a high pressure rating and a material that can withstand high temperatures.

- Water treatment plants: Select a flange with a material that is resistant to corrosion and can withstand high pressures.

Gallery of Flange Size Images

Flange Size Image Gallery

Frequently Asked Questions

What is the importance of flange size in piping systems?

+The flange size is critical in piping systems as it determines the amount of fluid that can flow through the pipe, as well as the amount of pressure that the pipe can withstand.

How do I choose the right flange size for my piping system?

+To choose the right flange size, you need to consider the nominal pipe size, pressure rating, material of the flange, and flange design. You can use a flange size calculator or consult the manufacturer's specifications to ensure accurate calculations.

What are the common mistakes to avoid when choosing a flange size?

+Common mistakes to avoid when choosing a flange size include choosing a flange that is too small or too large for the piping system, selecting a flange with an incorrect pressure rating or material, and failing to consult the manufacturer's specifications and recommendations.

What are the different types of flange sizes and how are they measured?

+Flange sizes are typically designated by a combination of numbers and letters, which indicate the nominal pipe size, pressure rating, and material of the flange. The nominal pipe size is usually measured in inches, while the pressure rating is measured in pounds per square inch (PSI).

What are the applications of flanges in piping systems?

+Flanges are used in a wide range of applications, including oil and gas pipelines, chemical processing plants, power generation plants, water treatment plants, and industrial piping systems.

In summary, choosing the right flange size is crucial for the safe and efficient operation of piping systems. By understanding the different types of flange sizes, considering the nominal pipe size, pressure rating, and material of the flange, and consulting the manufacturer's specifications and recommendations, you can ensure that your piping system operates at optimal levels. We hope that this article has provided you with valuable insights and tips on how to choose the right flange size for your specific application. If you have any further questions or comments, please do not hesitate to reach out to us. We would be happy to hear from you and provide any additional information or guidance that you may need.