Intro

Heat transfer printable vinyl is a versatile material used for various applications, including custom apparel, signs, and vehicle wraps. The importance of understanding the properties and uses of heat transfer vinyl cannot be overstated, as it has become a crucial tool for crafters, small business owners, and marketing professionals. In this article, we will delve into the world of heat transfer printable vinyl, exploring its benefits, working mechanisms, and steps for successful application.

The rise of heat transfer vinyl can be attributed to its ease of use, flexibility, and affordability. With the advancement of technology, heat transfer vinyl has become more accessible, allowing individuals to create professional-looking designs without extensive experience. Moreover, the material's durability and resistance to fading have made it a popular choice for outdoor and indoor applications. As the demand for custom products continues to grow, the knowledge of heat transfer vinyl has become essential for anyone looking to tap into this market.

The applications of heat transfer vinyl are diverse, ranging from custom t-shirts and hoodies to vehicle wraps and signage. The material's ability to adhere to various surfaces, including fabric, plastic, and metal, has made it a favorite among crafters and small business owners. Furthermore, the ease of cutting and weeding heat transfer vinyl has simplified the production process, allowing for faster turnaround times and increased productivity. As the industry continues to evolve, it is essential to stay up-to-date with the latest trends and techniques in heat transfer vinyl application.

Introduction to Heat Transfer Vinyl

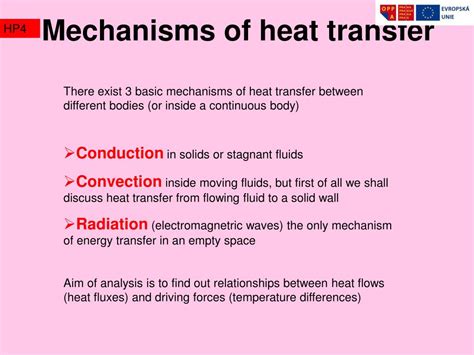

Heat transfer vinyl is a type of vinyl that is designed to be applied using heat and pressure. The material consists of a vinyl sheet with a heat-activated adhesive, which is applied to the desired surface using a heat press. The heat press applies high temperatures and pressure, causing the adhesive to melt and bond with the surface. This process creates a strong and durable bond, ensuring that the design remains in place for an extended period.

Types of Heat Transfer Vinyl

There are several types of heat transfer vinyl available, each with its unique characteristics and applications. Some of the most common types include:- Caldium-based heat transfer vinyl: This type of vinyl is known for its high durability and resistance to fading. It is commonly used for outdoor applications, such as vehicle wraps and signage.

- Polyurethane-based heat transfer vinyl: This type of vinyl is flexible and stretchy, making it ideal for applications that require a high degree of flexibility, such as custom apparel and sportswear.

- PVC-based heat transfer vinyl: This type of vinyl is affordable and easy to apply, making it a popular choice for crafters and small business owners.

Benefits of Heat Transfer Vinyl

Heat transfer vinyl offers several benefits, including:

- Ease of use: Heat transfer vinyl is relatively easy to apply, even for those with limited experience.

- Flexibility: Heat transfer vinyl can be applied to a variety of surfaces, including fabric, plastic, and metal.

- Durability: Heat transfer vinyl is resistant to fading and can withstand exposure to outdoor elements.

- Affordability: Heat transfer vinyl is a cost-effective solution for custom apparel and signage.

Applications of Heat Transfer Vinyl

Heat transfer vinyl has a wide range of applications, including:- Custom apparel: Heat transfer vinyl is commonly used for custom t-shirts, hoodies, and sportswear.

- Signage: Heat transfer vinyl is used for outdoor and indoor signage, including vehicle wraps and building signs.

- Crafting: Heat transfer vinyl is used for various crafting applications, including custom gifts and decorations.

Working Mechanisms of Heat Transfer Vinyl

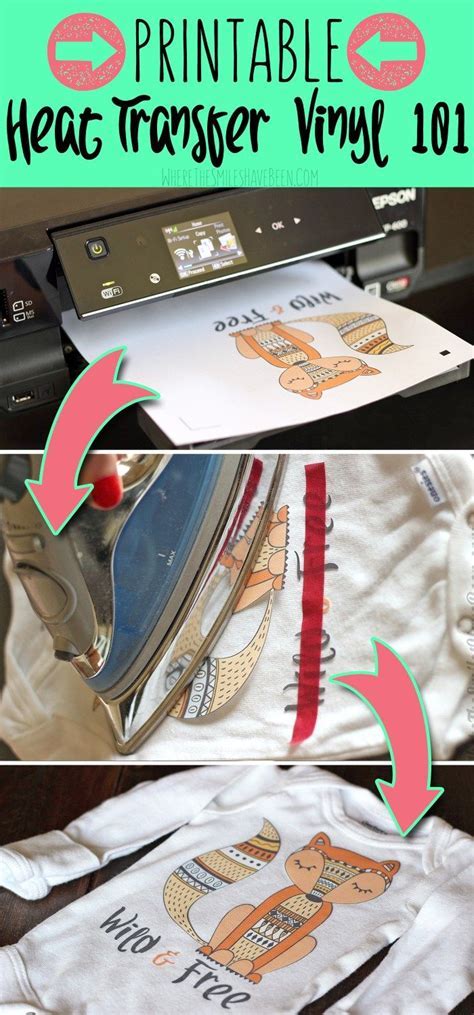

The working mechanisms of heat transfer vinyl involve the application of heat and pressure to activate the adhesive. This process can be broken down into several steps:

- Cutting: The heat transfer vinyl is cut into the desired shape and design using a cutting machine or scissors.

- Weeding: The excess vinyl is removed from the design, leaving only the desired image or text.

- Application: The heat transfer vinyl is applied to the desired surface using a heat press.

- Heat and pressure: The heat press applies high temperatures and pressure, causing the adhesive to melt and bond with the surface.

Steps for Successful Application

To ensure successful application of heat transfer vinyl, follow these steps:- Prepare the surface: Ensure the surface is clean and dry before applying the heat transfer vinyl.

- Apply the vinyl: Apply the heat transfer vinyl to the surface, ensuring it is centered and smooth.

- Apply heat and pressure: Apply heat and pressure using a heat press, following the manufacturer's instructions.

- Allow to cool: Allow the vinyl to cool before handling or washing.

Practical Examples and Statistical Data

Heat transfer vinyl has been used in various applications, including custom apparel and signage. According to a recent study, the demand for custom apparel is expected to increase by 10% in the next year, with heat transfer vinyl being a popular choice for manufacturers. Additionally, a survey of small business owners found that 75% of respondents use heat transfer vinyl for their signage and marketing materials.

Gallery of Heat Transfer Vinyl

Heat Transfer Vinyl Image Gallery

FAQs

What is heat transfer vinyl?

+Heat transfer vinyl is a type of vinyl that is designed to be applied using heat and pressure.

What are the benefits of heat transfer vinyl?

+Heat transfer vinyl offers several benefits, including ease of use, flexibility, durability, and affordability.

What are the applications of heat transfer vinyl?

+Heat transfer vinyl has a wide range of applications, including custom apparel, signage, crafting, and vehicle wraps.

How do I apply heat transfer vinyl?

+To apply heat transfer vinyl, cut the vinyl into the desired shape and design, weed the excess vinyl, apply the vinyl to the surface, and apply heat and pressure using a heat press.

What are the different types of heat transfer vinyl?

+There are several types of heat transfer vinyl, including caldium-based, polyurethane-based, and PVC-based heat transfer vinyl.

In conclusion, heat transfer vinyl is a versatile material that offers a wide range of benefits and applications. By understanding the properties and uses of heat transfer vinyl, individuals can create professional-looking designs and products with ease. We encourage readers to share their experiences and tips for working with heat transfer vinyl in the comments below. Additionally, we invite readers to explore our other articles and resources on heat transfer vinyl and related topics. Whether you are a crafter, small business owner, or marketing professional, heat transfer vinyl is an essential tool to have in your arsenal.