Intro

Discover expert 5 Tips HTV Vinyl techniques for crafting, cutting, and applying heat transfer vinyl designs with precision and ease, using tools like cutters and weeding tools.

The world of heat transfer vinyl (HTV) is a fascinating one, offering endless possibilities for crafters, DIY enthusiasts, and small business owners. With the rise of vinyl cutting machines and online tutorials, it's easier than ever to get started with HTV vinyl projects. However, like any craft, there are tips and tricks to help you achieve professional-looking results. In this article, we'll delve into the importance of understanding HTV vinyl, its benefits, and provide you with five valuable tips to enhance your crafting experience.

HTV vinyl has become a popular choice for customizing apparel, accessories, and home decor items. Its versatility, durability, and ease of use make it an ideal material for various applications. From creating personalized t-shirts and hoodies to designing custom phone cases and water bottles, the possibilities are endless. As you explore the world of HTV vinyl, you'll discover the numerous benefits it offers, including its ability to withstand repeated washing and wear, making it a great choice for everyday items.

As you begin your HTV vinyl journey, it's essential to understand the different types of vinyl available, including glossy, matte, metallic, and glitter. Each type has its unique characteristics, and choosing the right one for your project can make all the difference. With the right tools, materials, and knowledge, you can create stunning designs that will impress friends, family, and even potential customers. Whether you're a seasoned crafter or just starting out, the world of HTV vinyl is an exciting one, full of creative possibilities and opportunities to express yourself.

Understanding HTV Vinyl

Benefits of HTV Vinyl

The benefits of HTV vinyl are numerous, making it a popular choice for crafters and small business owners. Some of the advantages of using HTV vinyl include its durability, ease of use, and versatility. HTV vinyl can be applied to a wide range of fabrics, including cotton, polyester, and blends. It's also relatively easy to weed and cut, making it a great choice for beginners. Additionally, HTV vinyl is available in a variety of finishes, including glossy, matte, and metallic, allowing you to achieve the desired look for your project.Tip 1: Choose the Right Vinyl

Factors to Consider

When choosing the right vinyl, there are several factors to consider, including the fabric type, design, and desired finish. You should also consider the color and pattern of the vinyl, as well as the size and shape of the design. By taking these factors into account, you can ensure that your project turns out as expected and that you achieve the desired look.Tip 2: Prepare Your Fabric

Pre-Treatment Methods

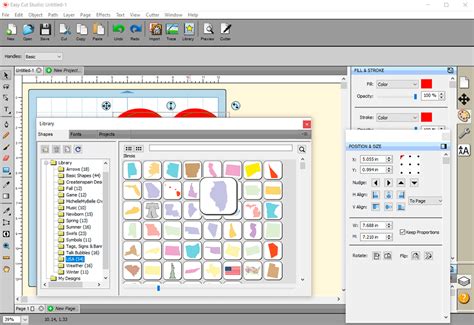

There are several pre-treatment methods you can use to prepare your fabric, including washing, drying, and ironing. You can also use a fabric finisher or a pre-treatment spray to help the vinyl adhere to the fabric. By using one or a combination of these methods, you can ensure that your fabric is ready for the HTV vinyl application.Tip 3: Use the Right Tools

Tool Maintenance

To ensure your tools continue to perform well, it's essential to maintain them properly. This includes cleaning and storing the tools after each use, as well as performing regular maintenance tasks such as replacing blades and updating software. By taking care of your tools, you can extend their lifespan and ensure they continue to produce high-quality results.Tip 4: Apply Heat and Pressure Correctly

Temperature and Pressure Guidelines

The temperature and pressure guidelines for HTV vinyl application will vary depending on the type of vinyl and fabric you're using. Generally, the temperature range is between 260°F to 320°F, and the pressure range is between 10-20 pounds per square inch. You should also consult the manufacturer's instructions for specific guidelines on temperature, pressure, and time.Tip 5: Weed and Cut with Precision

Weeding Techniques

There are several weeding techniques you can use to remove excess vinyl from your design. These include using a weeding tool, a scraper, or a pair of tweezers. You should also use a magnifying glass or a light box to help you see the small details in your design. By using the right weeding techniques, you can ensure that your designs are accurate and the vinyl is applied smoothly and evenly.HTV Vinyl Image Gallery

What is HTV vinyl?

+HTV vinyl, or heat transfer vinyl, is a type of vinyl that is designed to be applied to fabrics using heat and pressure.

What are the benefits of using HTV vinyl?

+The benefits of using HTV vinyl include its durability, ease of use, and versatility. It can be applied to a wide range of fabrics and is available in various finishes.

How do I choose the right HTV vinyl for my project?

+To choose the right HTV vinyl for your project, consider the fabric type, design, and desired finish. You should also consult the manufacturer's instructions for specific guidelines on temperature, pressure, and time.

What are the common mistakes to avoid when working with HTV vinyl?

+Common mistakes to avoid when working with HTV vinyl include not preparing the fabric properly, not applying heat and pressure correctly, and not weeding and cutting the vinyl with precision.

How do I troubleshoot common issues with HTV vinyl?

+To troubleshoot common issues with HTV vinyl, consult the manufacturer's instructions and online resources. You should also check the temperature, pressure, and time settings on your heat press and ensure that the vinyl is applied correctly.

As you continue to explore the world of HTV vinyl, remember that practice makes perfect. Don't be discouraged if your first projects don't turn out as expected – with time and patience, you'll develop the skills and techniques needed to achieve professional-looking results. Whether you're a seasoned crafter or just starting out, the world of HTV vinyl is an exciting one, full of creative possibilities and opportunities to express yourself. So, don't hesitate to share your projects, ask for advice, and learn from others in the crafting community. With the right tools, materials, and knowledge, you can unlock the full potential of HTV vinyl and create stunning designs that will impress and inspire others.