Intro

Master inventory control with 5 effective ways, leveraging stock management, supply chain optimization, and logistics strategies to boost efficiency and reduce costs, improving overall inventory management and business operations.

Effective inventory control is crucial for businesses to manage their stock levels, reduce costs, and improve customer satisfaction. In today's fast-paced and competitive market, having a well-organized inventory system can make all the difference between success and failure. In this article, we will explore the importance of inventory control and discuss five ways to achieve it.

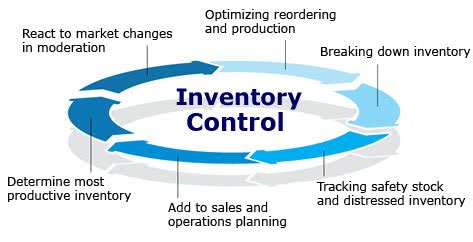

Inventory control is essential for businesses to ensure that they have the right products in stock, in the right quantities, and at the right time. It involves managing the flow of goods from procurement to delivery, and it requires careful planning, coordination, and execution. With effective inventory control, businesses can reduce stockouts, overstocking, and waste, which can lead to significant cost savings and improved profitability.

Moreover, inventory control can help businesses to improve their customer service by ensuring that products are available when customers need them. It can also help to reduce lead times, improve delivery times, and increase customer satisfaction. In addition, effective inventory control can provide businesses with valuable insights into their sales trends, customer behavior, and market demand, which can inform their marketing and sales strategies.

Introduction to Inventory Control

Inventory control is a critical component of supply chain management, and it involves a range of activities, including procurement, storage, handling, and distribution. It requires careful planning, coordination, and execution to ensure that products are available when and where they are needed. With the rise of e-commerce and omnichannel retailing, inventory control has become even more complex, and businesses need to be able to manage their inventory across multiple channels and locations.

Benefits of Inventory Control

The benefits of inventory control are numerous, and they include reduced costs, improved customer satisfaction, and increased profitability. By managing their inventory effectively, businesses can reduce stockouts, overstocking, and waste, which can lead to significant cost savings. They can also improve their customer service by ensuring that products are available when customers need them, which can lead to increased customer satisfaction and loyalty.

In addition, effective inventory control can provide businesses with valuable insights into their sales trends, customer behavior, and market demand, which can inform their marketing and sales strategies. It can also help businesses to improve their supply chain management, reduce lead times, and increase their competitiveness in the market.

5 Ways to Achieve Inventory Control

There are several ways to achieve inventory control, and the following are five effective methods:

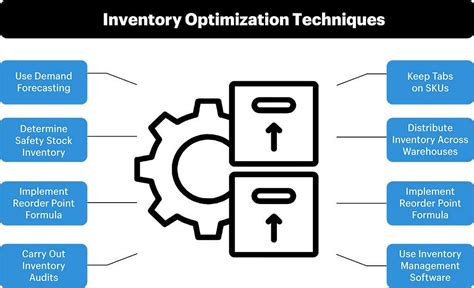

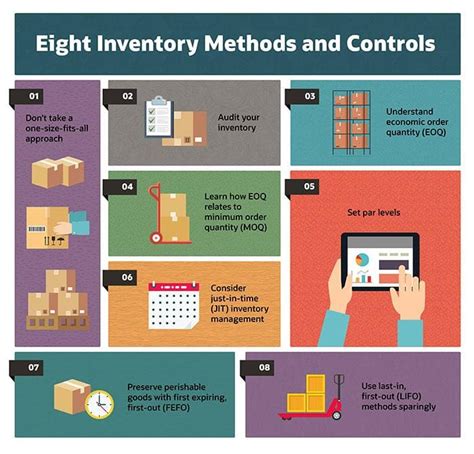

- Implement a Just-in-Time (JIT) System: A JIT system involves ordering and receiving inventory just in time to meet customer demand. This approach can help businesses to reduce their inventory levels, minimize waste, and improve their cash flow.

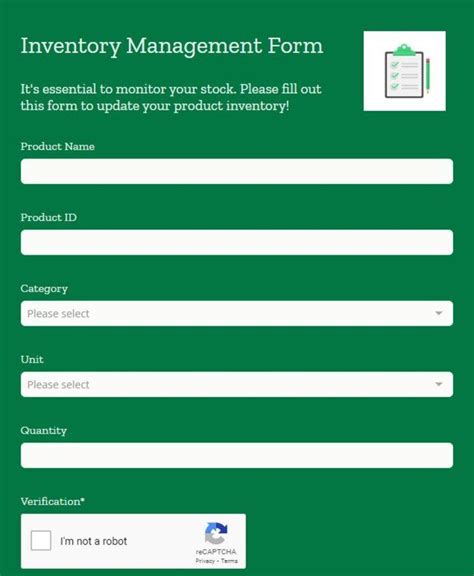

- Use Inventory Management Software: Inventory management software can help businesses to track their inventory levels, monitor their stock movements, and optimize their inventory control. It can also provide valuable insights into sales trends, customer behavior, and market demand.

- Conduct Regular Inventory Audits: Regular inventory audits can help businesses to identify discrepancies in their inventory levels, detect inventory shrinkage, and improve their inventory accuracy. They can also help businesses to identify areas for improvement and optimize their inventory control.

- Implement a Vendor-Managed Inventory (VMI) System: A VMI system involves partnering with suppliers to manage inventory levels, monitor stock movements, and optimize inventory control. This approach can help businesses to reduce their inventory costs, improve their supply chain management, and increase their competitiveness.

- Use Data Analytics: Data analytics can help businesses to gain valuable insights into their sales trends, customer behavior, and market demand. It can also help businesses to optimize their inventory control, reduce inventory costs, and improve their customer satisfaction.

Best Practices for Inventory Control

There are several best practices for inventory control, and the following are some effective methods:

- Monitor Inventory Levels: Monitoring inventory levels can help businesses to identify discrepancies, detect inventory shrinkage, and improve their inventory accuracy.

- Optimize Inventory Storage: Optimizing inventory storage can help businesses to reduce their inventory costs, improve their supply chain management, and increase their competitiveness.

- Implement a First-in-First-Out (FIFO) System: A FIFO system involves selling or using older inventory first to minimize waste and reduce inventory costs.

- Conduct Regular Inventory Counts: Regular inventory counts can help businesses to identify discrepancies, detect inventory shrinkage, and improve their inventory accuracy.

- Provide Training to Employees: Providing training to employees can help businesses to improve their inventory control, reduce inventory costs, and increase their customer satisfaction.

Common Challenges in Inventory Control

There are several common challenges in inventory control, and the following are some of the most significant ones:

- Inventory Obsolescence: Inventory obsolescence occurs when inventory becomes outdated or obsolete, which can lead to significant losses for businesses.

- Inventory Shrinkage: Inventory shrinkage occurs when inventory is lost, stolen, or damaged, which can lead to significant losses for businesses.

- Overstocking: Overstocking occurs when businesses order too much inventory, which can lead to significant costs and losses.

- Stockouts: Stockouts occur when businesses run out of inventory, which can lead to lost sales, damaged customer relationships, and significant costs.

- Supply Chain Disruptions: Supply chain disruptions can occur due to various factors, such as natural disasters, transportation disruptions, or supplier insolvency, which can lead to significant losses for businesses.

Gallery of Inventory Control Images

Inventory Control Image Gallery

What is inventory control?

+Inventory control is the process of managing and regulating the flow of goods from procurement to delivery. It involves tracking inventory levels, monitoring stock movements, and optimizing inventory control to minimize costs and maximize efficiency.

Why is inventory control important?

+Inventory control is important because it helps businesses to reduce costs, improve customer satisfaction, and increase profitability. Effective inventory control can also provide businesses with valuable insights into their sales trends, customer behavior, and market demand, which can inform their marketing and sales strategies.

What are some common challenges in inventory control?

+Some common challenges in inventory control include inventory obsolescence, inventory shrinkage, overstocking, stockouts, and supply chain disruptions. These challenges can lead to significant losses for businesses and can be mitigated through effective inventory control strategies and techniques.

How can businesses achieve effective inventory control?

+Businesses can achieve effective inventory control by implementing a range of strategies and techniques, including just-in-time systems, inventory management software, regular inventory audits, vendor-managed inventory systems, and data analytics. They can also optimize their inventory storage, implement first-in-first-out systems, conduct regular inventory counts, and provide training to employees.

What are some best practices for inventory control?

+Some best practices for inventory control include monitoring inventory levels, optimizing inventory storage, implementing first-in-first-out systems, conducting regular inventory counts, and providing training to employees. Businesses can also use data analytics to gain valuable insights into their sales trends, customer behavior, and market demand, which can inform their marketing and sales strategies.

In conclusion, inventory control is a critical component of supply chain management, and it requires careful planning, coordination, and execution to ensure that products are available when and where they are needed. By implementing effective inventory control strategies and techniques, businesses can reduce costs, improve customer satisfaction, and increase profitability. They can also gain valuable insights into their sales trends, customer behavior, and market demand, which can inform their marketing and sales strategies. We hope this article has provided you with valuable information and insights into inventory control, and we encourage you to share your thoughts and experiences in the comments section below.