Intro

Boost efficiency with 5 inventory management tips, including stock control, supply chain optimization, and warehouse management, to reduce costs and improve logistics, using effective inventory tracking and forecasting techniques.

Effective inventory management is crucial for businesses to maintain a competitive edge in today's fast-paced market. It involves balancing the need to have enough stock on hand to meet customer demand with the need to minimize unnecessary inventory costs. Proper inventory management can help businesses reduce waste, improve cash flow, and increase customer satisfaction. In this article, we will explore five essential inventory management tips that can help businesses optimize their inventory levels and improve their overall operations.

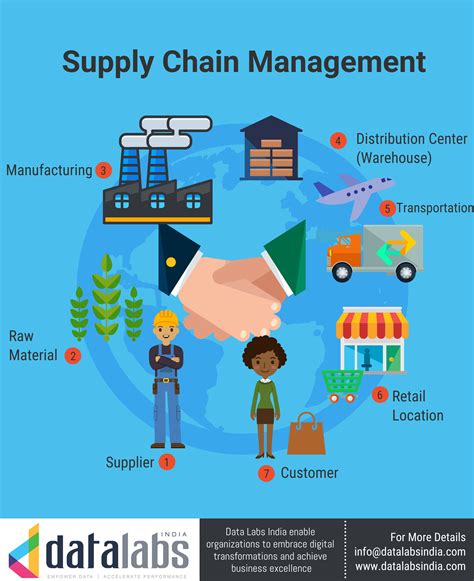

Inventory management is a vital aspect of any business, and its importance cannot be overstated. When done correctly, it can help businesses reduce costs, improve efficiency, and increase profitability. On the other hand, poor inventory management can lead to stockouts, overstocking, and wasted resources. With the rise of e-commerce and global supply chains, inventory management has become more complex than ever. Businesses must be able to adapt to changing market conditions, manage multiple suppliers, and meet evolving customer expectations.

In recent years, inventory management has become a critical component of business strategy. Companies that excel in inventory management are able to respond quickly to changes in demand, reduce lead times, and improve their overall competitiveness. Moreover, effective inventory management can help businesses build strong relationships with their suppliers, improve communication with their customers, and increase their revenue. As the business landscape continues to evolve, it is essential for companies to stay ahead of the curve by implementing effective inventory management strategies.

Understanding Inventory Management

Benefits of Inventory Management

The benefits of inventory management are numerous. Some of the most significant advantages include: * Reduced inventory costs: By optimizing inventory levels, businesses can minimize the costs associated with holding excess inventory. * Improved cash flow: Effective inventory management can help businesses free up cash that is tied up in inventory, allowing them to invest in other areas of the business. * Increased customer satisfaction: By having the right products in stock, businesses can improve customer satisfaction and reduce the risk of stockouts. * Improved supply chain management: Inventory management can help businesses build strong relationships with their suppliers, improve communication, and reduce lead times.Inventory Management Tips

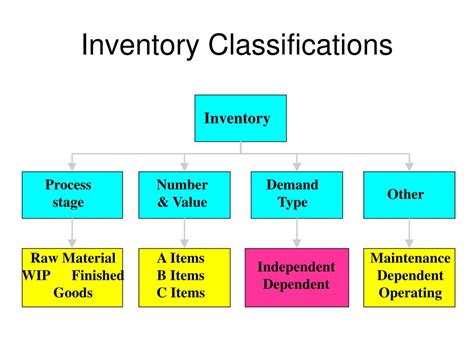

Best Practices for Inventory Management

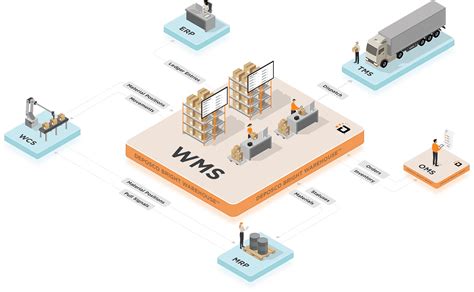

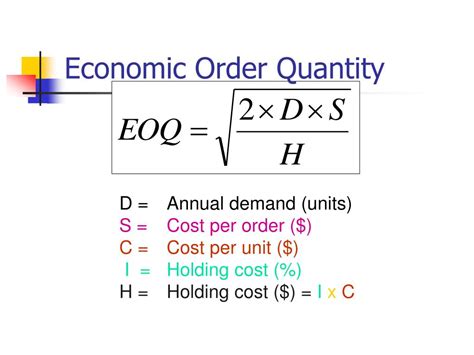

Some of the best practices for inventory management include: * **Tracking Inventory Levels**: Businesses should track their inventory levels regularly to identify trends, detect discrepancies, and optimize their inventory turnover. * **Using Barcoding and RFID Technology**: Barcoding and RFID technology can help businesses track their inventory levels, automate reporting, and improve their inventory accuracy. * **Implementing a Inventory Classification System**: An inventory classification system can help businesses categorize their inventory into different categories, prioritize their inventory management efforts, and optimize their inventory levels. * **Providing Inventory Management Training**: Providing inventory management training to employees can help businesses improve their inventory management skills, reduce errors, and improve their overall operations.Inventory Management Strategies

Inventory Management Tools and Techniques

Some of the most common inventory management tools and techniques include: * **Inventory Management Software**: Inventory management software can help businesses track their inventory levels, automate reporting, and optimize their inventory turnover. * **Barcoding and RFID Technology**: Barcoding and RFID technology can help businesses track their inventory levels, automate reporting, and improve their inventory accuracy. * **Spreadsheet Analysis**: Spreadsheet analysis can help businesses track their inventory levels, analyze trends, and optimize their inventory turnover. * **Inventory Management Apps**: Inventory management apps can help businesses track their inventory levels, automate reporting, and optimize their inventory turnover on-the-go.Common Inventory Management Mistakes

Inventory Management Trends

Some of the most significant inventory management trends include: * **Cloud-Based Inventory Management**: Cloud-based inventory management involves using cloud-based software to track and manage inventory levels, automate reporting, and optimize inventory turnover. * **Artificial Intelligence (AI) and Machine Learning (ML)**: AI and ML can help businesses analyze sales data, detect trends, and optimize their inventory levels. * **Internet of Things (IoT)**: IoT can help businesses track their inventory levels, automate reporting, and improve their inventory accuracy using RFID technology and sensors. * **Blockchain Technology**: Blockchain technology can help businesses track their inventory levels, automate reporting, and improve their inventory accuracy using a decentralized and secure ledger.Gallery of Inventory Management Images

Inventory Management Image Gallery

Frequently Asked Questions

What is inventory management?

+Inventory management refers to the process of planning, organizing, and controlling the flow of inventory from raw materials to finished goods.

Why is inventory management important?

+Inventory management is important because it helps businesses reduce waste, improve cash flow, and increase customer satisfaction.

What are some common inventory management mistakes?

+Some common inventory management mistakes include overstocking, understocking, inaccurate inventory tracking, and lack of inventory management training.

What are some inventory management trends?

+Some inventory management trends include cloud-based inventory management, artificial intelligence and machine learning, internet of things, and blockchain technology.

How can businesses improve their inventory management?

+Businesses can improve their inventory management by implementing inventory management software, using barcoding and RFID technology, providing inventory management training, and analyzing sales data and seasonal trends.

In conclusion, inventory management is a critical component of business operations that can help companies reduce waste, improve cash flow, and increase customer satisfaction. By implementing effective inventory management strategies, businesses can optimize their inventory levels, reduce costs, and improve their overall competitiveness. We encourage readers to share their thoughts and experiences on inventory management in the comments section below. Additionally, we invite readers to share this article with others who may benefit from the information and insights provided. By working together, we can help businesses improve their inventory management and achieve their goals.