Intro

Optimize inventory management with a high inventory turn rate, improving stock turnover, reducing waste, and increasing efficiency in supply chain operations and logistics management.

The importance of inventory management cannot be overstated, particularly when it comes to maintaining a healthy and profitable business. One key metric that plays a significant role in this process is the inventory turn rate, also known as inventory turnover. This measure indicates how often a company sells and replaces its inventory within a given period, typically a year. Understanding the significance of inventory turn rate and its impact on business operations is crucial for entrepreneurs, managers, and stakeholders alike. In this article, we will delve into the world of inventory management, exploring the concept of inventory turn rate, its calculation, benefits, and strategies to improve it.

Inventory turn rate is a vital indicator of a company's efficiency in managing its inventory. It reflects how well a business balances its stock levels with sales demand, avoiding both overstocking and understocking. A high inventory turn rate suggests that a company is selling its products quickly and replenishing its stock frequently, which can lead to increased revenue and reduced storage costs. On the other hand, a low inventory turn rate may indicate slow-moving products, overstocking, or inefficient supply chain management, ultimately resulting in wasted resources and decreased profitability.

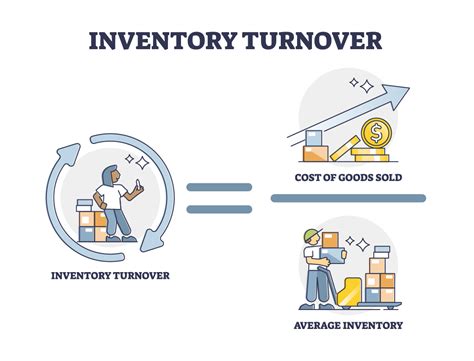

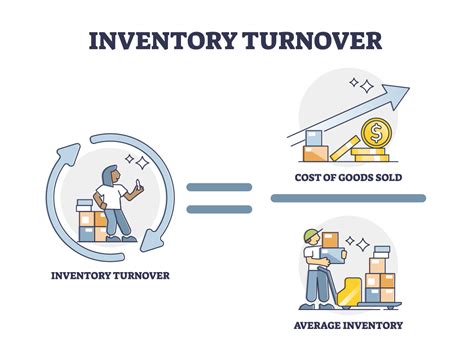

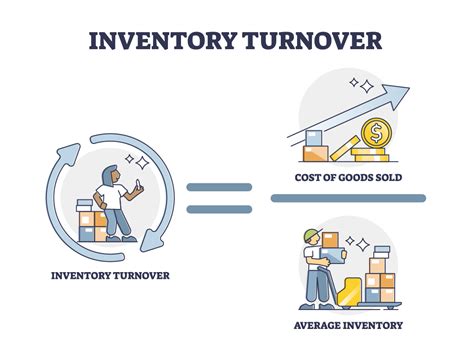

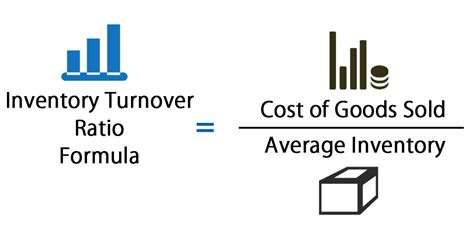

The calculation of inventory turn rate is relatively straightforward. It is computed by dividing the cost of goods sold by the average inventory value during a specific period. For instance, if a company's cost of goods sold for the year is $100,000 and its average inventory value is $20,000, the inventory turn rate would be 5 ($100,000 ÷ $20,000). This means that the company sold and replaced its entire inventory five times during that year. Understanding this metric and its implications is essential for making informed decisions about inventory management, pricing strategies, and supply chain optimization.

Understanding Inventory Turn Rate

To grasp the concept of inventory turn rate fully, it's essential to consider its components and how they interact. The cost of goods sold, for example, includes the direct costs associated with producing or purchasing the products, such as materials, labor, and overheads. The average inventory value, on the other hand, represents the total value of inventory held by the company during the period, taking into account both the quantity and the cost of the items. By analyzing these elements, businesses can identify areas for improvement and develop targeted strategies to enhance their inventory management practices.

Benefits of a High Inventory Turn Rate

A high inventory turn rate offers several benefits to businesses. Firstly, it indicates that products are selling well and quickly, which can lead to increased revenue and profitability. Secondly, it reduces the need for large storage facilities, as inventory is being sold and replaced rapidly, thereby minimizing storage costs. Thirdly, a high inventory turn rate can help companies avoid inventory obsolescence, where products become outdated or unsellable due to changes in market demand or technological advancements. Finally, it enables businesses to respond more effectively to changes in the market, as they are more agile and better positioned to adapt to shifting consumer preferences.Strategies to Improve Inventory Turn Rate

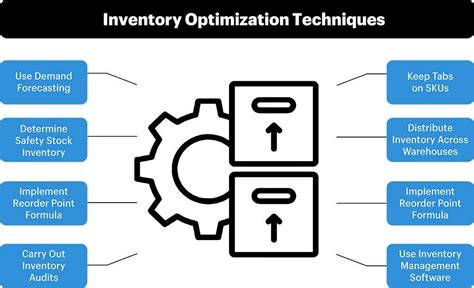

Improving inventory turn rate requires a multifaceted approach that involves optimizing various aspects of inventory management. One key strategy is to implement a just-in-time (JIT) inventory system, where products are ordered and received just in time to meet customer demand. This approach minimizes inventory holding costs and reduces the risk of overstocking. Another strategy is to conduct regular inventory audits to identify slow-moving products and implement measures to clear them out, such as discounts or promotions. Additionally, businesses can leverage data analytics and forecasting tools to better predict demand and adjust their inventory levels accordingly.

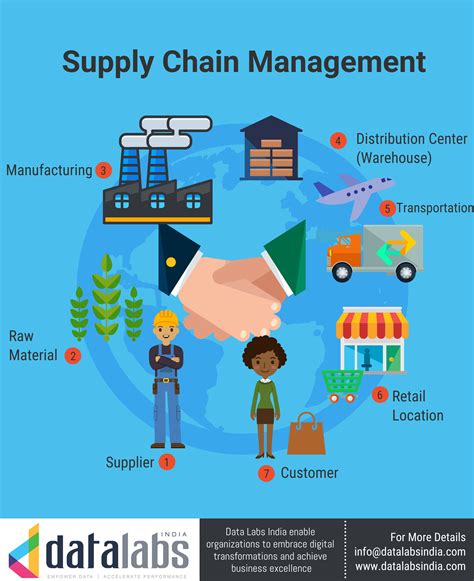

Effective inventory management also involves streamlining the supply chain to ensure that products are delivered quickly and efficiently. This can be achieved by building strong relationships with suppliers, investing in logistics and transportation infrastructure, and implementing efficient order fulfillment processes. Furthermore, companies can consider adopting a drop shipping model, where products are shipped directly from the supplier to the customer, eliminating the need for inventory storage and handling.

Best Practices for Inventory Management

To achieve a high inventory turn rate, businesses should adhere to several best practices. Firstly, they should maintain accurate and up-to-date inventory records, using tools such as inventory management software to track stock levels and monitor product movement. Secondly, they should implement a first-in, first-out (FIFO) inventory system, where older products are sold or used before newer ones, to minimize inventory obsolescence. Thirdly, they should conduct regular inventory reviews to identify areas for improvement and adjust their inventory management strategies accordingly.Common Challenges in Inventory Management

Despite its importance, inventory management can be a complex and challenging task. One common challenge is the difficulty in predicting demand accurately, which can lead to overstocking or understocking. Another challenge is the need to balance inventory levels with storage capacity and budget constraints. Additionally, businesses may face challenges in managing inventory across multiple locations or channels, such as e-commerce platforms, retail stores, and warehouses.

To overcome these challenges, companies can invest in inventory management software that provides real-time visibility into inventory levels, automates inventory tracking, and offers predictive analytics to forecast demand. They can also implement inventory management best practices, such as regular inventory audits, FIFO inventory systems, and just-in-time ordering. Furthermore, businesses can consider outsourcing inventory management to third-party logistics providers or hiring experienced inventory managers to oversee their inventory operations.

Technological Solutions for Inventory Management

The use of technology has revolutionized inventory management, providing businesses with powerful tools to optimize their inventory operations. Inventory management software, for example, enables companies to track inventory levels in real-time, automate inventory tracking, and analyze inventory data to identify trends and patterns. Additionally, technologies such as radio-frequency identification (RFID) and barcode scanning can help businesses to track inventory movement and automate inventory counting.Inventory Turn Rate and Business Performance

The inventory turn rate has a significant impact on business performance, influencing revenue, profitability, and competitiveness. A high inventory turn rate can lead to increased revenue and profitability, as products are sold quickly and efficiently. It can also enhance competitiveness, as businesses are better positioned to respond to changes in the market and adapt to shifting consumer preferences.

On the other hand, a low inventory turn rate can result in decreased revenue and profitability, as products remain in inventory for extended periods, tying up capital and resources. It can also lead to inventory obsolescence, where products become outdated or unsellable, resulting in wasted resources and decreased competitiveness.

Industry Benchmarks for Inventory Turn Rate

Industry benchmarks for inventory turn rate vary widely, depending on the sector, product type, and business model. In general, a high inventory turn rate is desirable, as it indicates efficient inventory management and a responsive supply chain. However, the optimal inventory turn rate will depend on the specific industry and business context.For example, in the retail sector, a high inventory turn rate is critical, as products are often seasonal or subject to rapid changes in consumer demand. In contrast, in the manufacturing sector, a lower inventory turn rate may be acceptable, as products may have a longer shelf life and be less subject to changes in demand.

Gallery of Inventory Management

Inventory Management Image Gallery

FAQs

What is inventory turn rate, and why is it important?

+Inventory turn rate, also known as inventory turnover, measures how often a company sells and replaces its inventory within a given period. It is essential because it indicates a company's efficiency in managing its inventory, balancing stock levels with sales demand, and avoiding overstocking and understocking.

How is inventory turn rate calculated?

+Inventory turn rate is calculated by dividing the cost of goods sold by the average inventory value during a specific period.

What are the benefits of a high inventory turn rate?

+A high inventory turn rate offers several benefits, including increased revenue and profitability, reduced storage costs, and improved responsiveness to changes in the market.

How can businesses improve their inventory turn rate?

+Businesses can improve their inventory turn rate by implementing a just-in-time inventory system, conducting regular inventory audits, leveraging data analytics and forecasting tools, and streamlining their supply chain.

What are the common challenges in inventory management?

+Common challenges in inventory management include predicting demand accurately, balancing inventory levels with storage capacity and budget constraints, and managing inventory across multiple locations or channels.

In conclusion, inventory turn rate is a critical metric that plays a significant role in inventory management and business performance. By understanding the concept of inventory turn rate, its calculation, benefits, and strategies to improve it, businesses can optimize their inventory operations, reduce costs, and enhance their competitiveness. As the business landscape continues to evolve, it is essential for companies to stay ahead of the curve by adopting effective inventory management practices, leveraging technological solutions, and continuously monitoring and improving their inventory turn rate. We invite you to share your thoughts and experiences on inventory management and its impact on business performance. Please comment below, and let's continue the conversation.