Intro

Learn the inventory turnover equation to optimize stock levels, reduce waste, and improve supply chain efficiency with our comprehensive guide on inventory management and calculation techniques.

The inventory turnover equation is a crucial metric for businesses to evaluate their inventory management efficiency. It measures how many times a company sells and replaces its inventory within a given period, typically a year. This equation is vital for companies to determine their inventory levels, manage cash flow, and make informed decisions about production and pricing. In this article, we will delve into the importance of the inventory turnover equation, its calculation, and its implications for businesses.

The inventory turnover equation is essential for businesses because it helps them strike a balance between inventory levels and sales. Holding too much inventory can lead to waste, obsolescence, and unnecessary storage costs, while having too little inventory can result in lost sales and dissatisfied customers. By calculating the inventory turnover, businesses can identify areas for improvement and optimize their inventory management strategies. For instance, a high inventory turnover rate may indicate that a company is selling its products quickly, but it may also suggest that the company is not holding enough inventory to meet demand.

Effective inventory management is critical for businesses to stay competitive in today's fast-paced market. The inventory turnover equation provides valuable insights into a company's operational efficiency, helping managers to identify bottlenecks and areas for improvement. By analyzing the inventory turnover rate, businesses can adjust their production schedules, manage their supply chains, and make informed decisions about pricing and promotions. Moreover, a well-managed inventory can help companies to reduce waste, minimize losses, and improve their overall profitability.

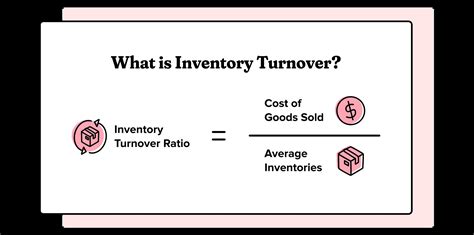

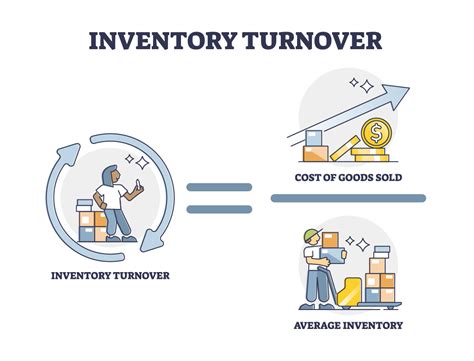

Understanding the Inventory Turnover Equation

The inventory turnover equation is calculated by dividing the cost of goods sold (COGS) by the average inventory level. The COGS represents the direct costs associated with producing and selling a company's products, while the average inventory level is the total value of inventory held by the company during a given period. The inventory turnover equation is as follows:

Inventory Turnover = COGS / Average Inventory

For example, if a company has a COGS of $100,000 and an average inventory level of $20,000, its inventory turnover would be 5. This means that the company sells and replaces its inventory five times within a given period.

Calculating the Inventory Turnover Rate

To calculate the inventory turnover rate, businesses need to follow these steps:- Determine the COGS: Calculate the total direct costs associated with producing and selling the company's products.

- Calculate the average inventory level: Add the beginning and ending inventory levels and divide by 2.

- Divide the COGS by the average inventory level: Calculate the inventory turnover rate by dividing the COGS by the average inventory level.

For instance, if a company has a COGS of $50,000, a beginning inventory level of $10,000, and an ending inventory level of $15,000, its average inventory level would be ($10,000 + $15,000) / 2 = $12,500. The inventory turnover rate would be $50,000 / $12,500 = 4.

Interpreting the Inventory Turnover Rate

The inventory turnover rate provides valuable insights into a company's inventory management efficiency. A high inventory turnover rate indicates that a company is selling its products quickly and efficiently, while a low inventory turnover rate suggests that the company is holding too much inventory. Here are some general guidelines for interpreting the inventory turnover rate:

- High inventory turnover rate (above 5): The company is selling its products quickly and efficiently.

- Medium inventory turnover rate (between 3 and 5): The company is managing its inventory levels effectively.

- Low inventory turnover rate (below 3): The company is holding too much inventory and may need to adjust its production schedules or pricing strategies.

Factors Affecting the Inventory Turnover Rate

Several factors can affect the inventory turnover rate, including:- Seasonal fluctuations: Companies that experience seasonal fluctuations in demand may need to adjust their inventory levels accordingly.

- Product lifecycle: Companies that produce products with a short lifecycle may need to manage their inventory levels more aggressively.

- Supply chain efficiency: Companies with efficient supply chains may be able to manage their inventory levels more effectively.

- Pricing strategies: Companies that use pricing strategies such as discounts or promotions may need to adjust their inventory levels accordingly.

Improving the Inventory Turnover Rate

To improve the inventory turnover rate, businesses can implement several strategies, including:

- Implementing just-in-time (JIT) inventory management: JIT inventory management involves producing and delivering products just in time to meet customer demand.

- Using inventory management software: Inventory management software can help businesses to track their inventory levels, manage their supply chains, and optimize their production schedules.

- Conducting regular inventory audits: Regular inventory audits can help businesses to identify areas for improvement and optimize their inventory management strategies.

- Adjusting pricing strategies: Businesses can adjust their pricing strategies to stimulate demand and improve their inventory turnover rate.

Best Practices for Inventory Management

To optimize their inventory management strategies, businesses should follow these best practices:- Monitor inventory levels regularly: Businesses should track their inventory levels regularly to identify areas for improvement.

- Implement a first-in, first-out (FIFO) inventory management system: FIFO inventory management involves selling the oldest products first to minimize waste and obsolescence.

- Use inventory management software: Inventory management software can help businesses to track their inventory levels, manage their supply chains, and optimize their production schedules.

- Conduct regular inventory audits: Regular inventory audits can help businesses to identify areas for improvement and optimize their inventory management strategies.

Inventory Turnover Equation Example

Let's consider an example of a company that produces and sells clothing. The company has a COGS of $200,000 and an average inventory level of $40,000. The inventory turnover rate would be $200,000 / $40,000 = 5. This means that the company sells and replaces its inventory five times within a given period.

Inventory Turnover Equation Case Study

A case study of a company that implemented an inventory management system found that the company was able to improve its inventory turnover rate by 20%. The company achieved this by implementing a JIT inventory management system, using inventory management software, and conducting regular inventory audits. As a result, the company was able to reduce its inventory levels, minimize waste and obsolescence, and improve its overall profitability.Inventory Turnover Image Gallery

What is the inventory turnover equation?

+The inventory turnover equation is a metric that measures how many times a company sells and replaces its inventory within a given period.

How is the inventory turnover rate calculated?

+The inventory turnover rate is calculated by dividing the cost of goods sold (COGS) by the average inventory level.

What are the factors that affect the inventory turnover rate?

+The factors that affect the inventory turnover rate include seasonal fluctuations, product lifecycle, supply chain efficiency, and pricing strategies.

How can businesses improve their inventory turnover rate?

+Businesses can improve their inventory turnover rate by implementing just-in-time (JIT) inventory management, using inventory management software, conducting regular inventory audits, and adjusting pricing strategies.

What are the benefits of optimizing inventory management?

+The benefits of optimizing inventory management include reducing waste and obsolescence, minimizing losses, and improving overall profitability.

In conclusion, the inventory turnover equation is a vital metric for businesses to evaluate their inventory management efficiency. By calculating the inventory turnover rate, businesses can identify areas for improvement and optimize their inventory management strategies. We hope this article has provided you with valuable insights into the inventory turnover equation and its importance for businesses. If you have any questions or comments, please feel free to share them below. Additionally, if you found this article helpful, please share it with your friends and colleagues who may benefit from learning about the inventory turnover equation.