Intro

Discover the Par Level Meaning Explained, understanding inventory management, stock control, and replenishment strategies to optimize supply chain efficiency and minimize stockouts.

Understanding the concept of par level is crucial in various industries, including hospitality, healthcare, and inventory management. The par level refers to the minimum quantity of a particular item that should be maintained in stock to meet the average demand. It serves as a threshold, indicating when it's necessary to replenish supplies to avoid running out of essential items. In this article, we will delve into the importance of par levels, their benefits, and how they are calculated and implemented in different sectors.

Maintaining optimal par levels is vital for businesses to ensure they can meet customer demands efficiently. For instance, in the hospitality industry, running out of linens, toiletries, or food items can lead to customer dissatisfaction and negatively impact the business's reputation. Similarly, in healthcare settings, having adequate supplies of medical equipment and consumables is critical for providing quality care. By setting and maintaining appropriate par levels, organizations can balance the need to have sufficient stock on hand with the costs associated with holding inventory.

Effective inventory management is key to the success of any business that deals with physical goods. It involves understanding the demand for products, managing stock levels, and ensuring that the right products are available at the right time. Par levels play a central role in this process by helping managers determine when to order more stock. This prevents overstocking, which can lead to waste and unnecessary storage costs, and understocking, which can result in lost sales and disappointed customers. By maintaining the optimal par level, businesses can strike a balance between these extremes and operate more efficiently.

Understanding Par Levels

To understand par levels fully, it's essential to consider the factors that influence them. These include the average usage rate of the item, the lead time required to replenish stock, and the desired service level. The average usage rate is the quantity of an item used over a specific period, while the lead time is the duration between placing an order and receiving the shipment. The desired service level refers to the percentage of time that the item should be available when demanded. By analyzing these factors, businesses can calculate the optimal par level for each item in their inventory.

Calculating Par Levels

Calculating par levels involves a straightforward formula that takes into account the average daily usage and the lead time for replenishment. The formula is: Par Level = (Average Daily Usage x Lead Time) + Safety Stock. Safety stock is an additional quantity of inventory held to protect against stockouts due to uncertainties in demand or supply. By adjusting the safety stock level, businesses can manage their risk tolerance and balance it with the costs of holding excess inventory.Benefits of Par Levels

Implementing par levels offers several benefits to organizations. It helps in reducing stockouts and overstocking, which can lead to significant cost savings. By maintaining the right amount of inventory, businesses can minimize waste and reduce the need for emergency orders, which are often more expensive. Additionally, par levels improve customer satisfaction by ensuring that products are available when needed. This leads to increased customer loyalty and positive word-of-mouth, which are vital for the long-term success of any business.

Implementing Par Levels

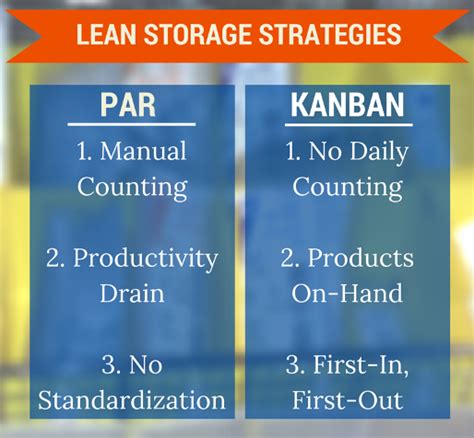

Implementing par levels requires a systematic approach. It starts with identifying the items that are critical to the business and calculating their par levels. This involves gathering historical data on usage rates and lead times. Once the par levels are determined, the next step is to establish a system for monitoring inventory levels and triggering orders when the par level is reached. This can be done manually through periodic inventory checks or automated through the use of inventory management software.Par Levels in Different Industries

The application of par levels varies across different industries, but the principle remains the same: to ensure that the right quantity of inventory is available to meet demand. In the hospitality industry, par levels are crucial for managing linens, amenities, and food supplies. In healthcare, par levels are vital for medical supplies and equipment. In manufacturing, par levels are used to manage raw materials and components. By understanding the specific needs and challenges of each industry, businesses can tailor their par level strategies to achieve optimal inventory management.

Challenges and Limitations

While par levels are a powerful tool for inventory management, there are challenges and limitations to their implementation. One of the main challenges is accurately forecasting demand, as unexpected changes can render par levels ineffective. Another challenge is managing inventory in environments with high variability in demand or lead times. Additionally, the implementation of par levels requires significant upfront investment in data collection and analysis, as well as ongoing monitoring and adjustment.Best Practices for Par Level Management

To get the most out of par level management, businesses should follow best practices. This includes regularly reviewing and adjusting par levels to reflect changes in demand or supply conditions. Implementing a just-in-time (JIT) inventory system can also help in minimizing inventory levels while maintaining the ability to meet demand. Additionally, using technology, such as inventory management software, can automate the process of tracking inventory levels and triggering orders, making par level management more efficient and less prone to errors.

Technology in Par Level Management

Technology plays a critical role in modern inventory management, including the implementation and maintenance of par levels. Inventory management software can track inventory levels in real-time, automatically generate orders when par levels are reached, and provide analytics to help in adjusting par levels based on historical data and forecasts. Barcode scanning and RFID technologies can also improve the accuracy of inventory tracking, reducing the likelihood of stockouts or overstocking due to inventory discrepancies.Conclusion and Future Directions

In conclusion, par levels are a fundamental concept in inventory management that helps businesses balance the need to meet customer demand with the costs of holding inventory. By understanding how to calculate and implement par levels, organizations can improve their operational efficiency, reduce costs, and enhance customer satisfaction. As technology continues to evolve, we can expect to see more sophisticated inventory management systems that integrate par level management with other supply chain functions, offering even greater benefits to businesses.

Final Thoughts

The importance of par levels in inventory management cannot be overstated. By adopting a systematic approach to par level management, businesses can navigate the complexities of inventory management with greater ease, ensuring they are always prepared to meet customer demand while minimizing waste and excess inventory. Whether you are in the hospitality industry, healthcare, or any other sector that relies on inventory, understanding and implementing par levels is crucial for achieving operational excellence.Par Level Image Gallery

What is the purpose of par levels in inventory management?

+The purpose of par levels is to ensure that the minimum quantity of an item is maintained in stock to meet the average demand, thus preventing stockouts and overstocking.

How are par levels calculated?

+Par levels are calculated using the formula: Par Level = (Average Daily Usage x Lead Time) + Safety Stock. This takes into account the average usage rate, lead time for replenishment, and a safety stock to protect against uncertainties.

What are the benefits of implementing par levels?

+The benefits include reducing stockouts and overstocking, minimizing waste, reducing the need for emergency orders, and improving customer satisfaction by ensuring products are available when needed.

Can technology improve par level management?

+Yes, technology such as inventory management software can automate the tracking of inventory levels, generate orders when par levels are reached, and provide analytics to adjust par levels based on historical data and forecasts.

How often should par levels be reviewed and adjusted?

+Par levels should be reviewed and adjusted regularly to reflect changes in demand or supply conditions. This could be monthly, quarterly, or annually, depending on the business and the specific items in inventory.

We hope this comprehensive guide to par levels has been informative and helpful. Whether you are a seasoned professional or just starting to explore the world of inventory management, understanding par levels is crucial for achieving operational efficiency and customer satisfaction. Feel free to share your thoughts, ask questions, or seek further clarification on any of the topics discussed. Your engagement is valued, and we look forward to hearing from you.