Intro

The world of sublimation printing has revolutionized the way we create custom designs on various materials, and printable sublimation vinyl is one of the most popular mediums for this technique. With its ease of use and versatility, printable sublimation vinyl has become a favorite among crafters, small business owners, and hobbyists alike. In this comprehensive guide, we will delve into the world of printable sublimation vinyl, exploring its benefits, working mechanisms, and steps to achieve professional-looking results.

Printable sublimation vinyl is a special type of vinyl that is coated with a sublimation receptive layer, allowing it to accept sublimation ink and transfer the design onto a substrate. This process involves heat, pressure, and time, which causes the ink to change from a solid to a gas state, bonding with the substrate and creating a permanent, full-color image. The result is a vibrant, photo-quality design that is both durable and long-lasting.

The benefits of using printable sublimation vinyl are numerous. For one, it offers a wide range of creative possibilities, from custom signs and banners to personalized gifts and apparel. Additionally, printable sublimation vinyl is relatively easy to use, requiring minimal equipment and expertise. With the right tools and techniques, anyone can achieve professional-looking results, making it an ideal medium for small businesses and hobbyists.

Introduction to Printable Sublimation Vinyl

To get started with printable sublimation vinyl, it's essential to understand the different types of vinyl available. There are several brands and varieties on the market, each with its own unique characteristics and features. Some popular types of printable sublimation vinyl include:

- Sublimation vinyl sheets: These are individual sheets of vinyl that can be cut to size and used for various applications.

- Sublimation vinyl rolls: These are large rolls of vinyl that can be used for high-volume printing and cutting.

- Sublimation vinyl bundles: These are packages that include multiple sheets or rolls of vinyl, often at a discounted price.

When choosing a printable sublimation vinyl, consider factors such as the substrate you'll be using, the desired finish, and the level of durability required. Some popular substrates for sublimation printing include ceramic, glass, metal, and fabric.

Benefits of Using Printable Sublimation Vinyl

The benefits of using printable sublimation vinyl are numerous. Some of the most significant advantages include:

- Vibrant, photo-quality images: Sublimation printing produces bright, vivid colors that are resistant to fading and cracking.

- Durable and long-lasting: Sublimation prints are permanent and can withstand exposure to sunlight, water, and other environmental factors.

- Versatile: Printable sublimation vinyl can be used on a wide range of substrates, from ceramics and glass to metal and fabric.

- Easy to use: With the right equipment and techniques, anyone can achieve professional-looking results with printable sublimation vinyl.

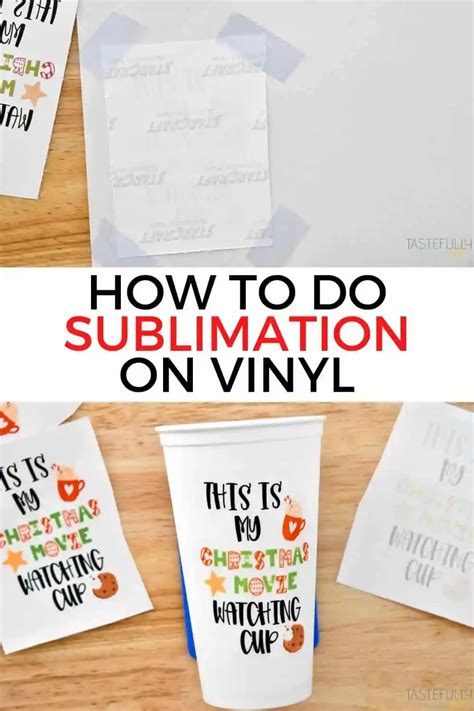

To achieve the best results with printable sublimation vinyl, it's essential to follow a few key steps. These include:

- Preparing the substrate: Ensure the substrate is clean, dry, and free of dust and debris.

- Designing the image: Use a software program to create a design, taking into account the size, resolution, and color profile of the substrate.

- Printing the image: Use a sublimation printer to print the design onto the vinyl, following the manufacturer's instructions for temperature, pressure, and time.

- Applying the vinyl: Use a heat press or other application tool to apply the vinyl to the substrate, following the manufacturer's instructions for temperature, pressure, and time.

Working Mechanisms of Printable Sublimation Vinyl

The working mechanisms of printable sublimation vinyl involve a combination of heat, pressure, and time. When the vinyl is exposed to heat, the sublimation ink changes from a solid to a gas state, bonding with the substrate and creating a permanent, full-color image. The pressure and time required for this process vary depending on the substrate and the desired finish.

Some popular substrates for sublimation printing include:

- Ceramic: Mugs, plates, and other ceramic items can be sublimated with vibrant, photo-quality images.

- Glass: Glass substrates, such as wine glasses and ornaments, can be sublimated with beautiful, delicate designs.

- Metal: Metal substrates, such as aluminum and stainless steel, can be sublimated with durable, long-lasting images.

- Fabric: Fabric substrates, such as t-shirts and tote bags, can be sublimated with soft, breathable images.

To achieve the best results with printable sublimation vinyl, it's essential to follow the manufacturer's instructions for temperature, pressure, and time. Additionally, consider factors such as the substrate's surface finish, the desired image resolution, and the level of durability required.

Steps to Achieve Professional-Looking Results

To achieve professional-looking results with printable sublimation vinyl, follow these steps:

- Prepare the substrate: Ensure the substrate is clean, dry, and free of dust and debris.

- Design the image: Use a software program to create a design, taking into account the size, resolution, and color profile of the substrate.

- Print the image: Use a sublimation printer to print the design onto the vinyl, following the manufacturer's instructions for temperature, pressure, and time.

- Apply the vinyl: Use a heat press or other application tool to apply the vinyl to the substrate, following the manufacturer's instructions for temperature, pressure, and time.

- Inspect and finish: Inspect the finished product for any defects or imperfections, and apply a finish such as a clear coat or laminate to protect the image.

By following these steps and using the right equipment and techniques, anyone can achieve professional-looking results with printable sublimation vinyl. Whether you're a crafter, small business owner, or hobbyist, this versatile medium offers a wide range of creative possibilities and opportunities for growth and development.

Common Mistakes to Avoid

When working with printable sublimation vinyl, there are several common mistakes to avoid. These include:

- Using the wrong substrate: Ensure the substrate is compatible with sublimation printing and follows the manufacturer's instructions.

- Incorrect temperature and pressure: Follow the manufacturer's instructions for temperature, pressure, and time to achieve the best results.

- Insufficient preparation: Ensure the substrate is clean, dry, and free of dust and debris before applying the vinyl.

- Poor design: Use a software program to create a design, taking into account the size, resolution, and color profile of the substrate.

By avoiding these common mistakes and following the right techniques, you can achieve professional-looking results with printable sublimation vinyl and take your crafting or business to the next level.

Tips and Tricks

Here are some tips and tricks to help you get the most out of printable sublimation vinyl:

- Use a high-quality sublimation printer and ink to achieve vibrant, photo-quality images.

- Experiment with different substrates and designs to find what works best for you.

- Follow the manufacturer's instructions for temperature, pressure, and time to achieve the best results.

- Use a heat press or other application tool to apply the vinyl to the substrate, following the manufacturer's instructions.

- Inspect and finish the product to ensure a professional-looking result.

By following these tips and tricks, you can achieve professional-looking results with printable sublimation vinyl and take your crafting or business to the next level.

Gallery of Printable Sublimation Vinyl

Printable Sublimation Vinyl Image Gallery

What is printable sublimation vinyl?

+Printable sublimation vinyl is a special type of vinyl that is coated with a sublimation receptive layer, allowing it to accept sublimation ink and transfer the design onto a substrate.

What are the benefits of using printable sublimation vinyl?

+The benefits of using printable sublimation vinyl include vibrant, photo-quality images, durability, and versatility. It can be used on a wide range of substrates, from ceramics and glass to metal and fabric.

How do I achieve professional-looking results with printable sublimation vinyl?

+To achieve professional-looking results with printable sublimation vinyl, follow the manufacturer's instructions for temperature, pressure, and time, and use a high-quality sublimation printer and ink. Additionally, ensure the substrate is clean, dry, and free of dust and debris before applying the vinyl.

What are some common mistakes to avoid when working with printable sublimation vinyl?

+Some common mistakes to avoid when working with printable sublimation vinyl include using the wrong substrate, incorrect temperature and pressure, insufficient preparation, and poor design.

What are some tips and tricks for getting the most out of printable sublimation vinyl?

+Some tips and tricks for getting the most out of printable sublimation vinyl include using a high-quality sublimation printer and ink, experimenting with different substrates and designs, and following the manufacturer's instructions for temperature, pressure, and time.

In summary, printable sublimation vinyl is a versatile and powerful medium that offers a wide range of creative possibilities. By following the right techniques and using the right equipment, anyone can achieve professional-looking results with this medium. Whether you're a crafter, small business owner, or hobbyist, printable sublimation vinyl is an ideal choice for creating custom designs on various substrates. We invite you to share your experiences and tips for working with printable sublimation vinyl in the comments below, and to explore the many resources and tutorials available online to help you get the most out of this exciting medium.