Intro

Discover 5 ways inventory tracking boosts efficiency, reduces stockouts, and optimizes supply chain management with automated inventory systems, barcode scanning, and data analytics for accurate inventory control and improved logistics management.

Effective inventory management is crucial for businesses of all sizes, as it directly impacts their bottom line. One of the key components of inventory management is inventory tracking, which involves monitoring and recording the movement of goods within a warehouse or storage facility. In this article, we will explore five ways inventory tracking can benefit your business and provide tips on how to implement an effective inventory tracking system.

Inventory tracking is essential for maintaining accurate inventory levels, reducing stockouts and overstocking, and improving overall operational efficiency. By implementing an inventory tracking system, businesses can gain real-time visibility into their inventory levels, allowing them to make informed decisions about production, shipping, and replenishment. In addition, inventory tracking can help businesses identify areas for improvement, such as reducing waste and minimizing losses due to theft or damage.

Benefits of Inventory Tracking

The benefits of inventory tracking are numerous, and can have a significant impact on a business's operations and profitability. Some of the key benefits include improved accuracy, reduced costs, and increased efficiency. By implementing an inventory tracking system, businesses can reduce the time spent on manual inventory counting and reconciliation, freeing up staff to focus on more strategic activities. Additionally, inventory tracking can help businesses identify trends and patterns in their inventory levels, allowing them to make more informed decisions about production and replenishment.

Improved Accuracy

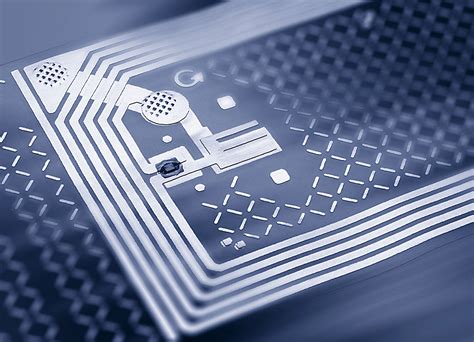

Inventory tracking can help businesses improve the accuracy of their inventory levels, reducing the risk of stockouts and overstocking. By using automated tracking systems, such as barcode scanning or RFID tags, businesses can quickly and accurately track the movement of goods within their warehouse or storage facility. This can help reduce errors and discrepancies, ensuring that inventory levels are always up-to-date and accurate.Types of Inventory Tracking Systems

There are several types of inventory tracking systems available, each with its own unique features and benefits. Some of the most common types of inventory tracking systems include manual tracking, automated tracking, and hybrid tracking systems. Manual tracking systems involve manually counting and recording inventory levels, while automated tracking systems use technology such as barcode scanning or RFID tags to track inventory levels. Hybrid tracking systems combine elements of both manual and automated tracking systems, providing a flexible and scalable solution for businesses of all sizes.

Manual Tracking Systems

Manual tracking systems involve manually counting and recording inventory levels, often using spreadsheets or paper-based systems. While manual tracking systems can be effective for small businesses or those with simple inventory management needs, they can be time-consuming and prone to errors. Additionally, manual tracking systems may not provide real-time visibility into inventory levels, making it difficult for businesses to make informed decisions about production and replenishment.Implementing an Inventory Tracking System

Implementing an inventory tracking system can be a complex and time-consuming process, requiring careful planning and consideration. Some of the key steps involved in implementing an inventory tracking system include assessing business needs, selecting a tracking system, and training staff. By following these steps and carefully evaluating business needs, businesses can ensure that their inventory tracking system is effective, efficient, and scalable.

Assessing Business Needs

The first step in implementing an inventory tracking system is to assess business needs, including the type and volume of inventory, as well as the level of tracking required. This can involve evaluating current inventory management processes, identifying areas for improvement, and determining the key features and functionalities required in an inventory tracking system. By carefully assessing business needs, businesses can ensure that their inventory tracking system is tailored to their specific requirements, providing a flexible and scalable solution.Best Practices for Inventory Tracking

There are several best practices for inventory tracking that businesses can follow to ensure that their inventory tracking system is effective and efficient. Some of the key best practices include regularly reviewing and updating inventory levels, using automated tracking systems, and providing training and support to staff. By following these best practices, businesses can ensure that their inventory tracking system is accurate, reliable, and scalable, providing real-time visibility into inventory levels and enabling informed decision-making.

Regularly Reviewing and Updating Inventory Levels

Regularly reviewing and updating inventory levels is essential for maintaining accurate and up-to-date inventory records. This can involve scheduling regular inventory counts, using automated tracking systems to monitor inventory levels, and updating inventory records in real-time. By regularly reviewing and updating inventory levels, businesses can ensure that their inventory tracking system is accurate and reliable, reducing the risk of stockouts and overstocking.Common Inventory Tracking Mistakes

There are several common inventory tracking mistakes that businesses can make, including failing to regularly review and update inventory levels, using inaccurate or outdated tracking systems, and failing to provide training and support to staff. By being aware of these common mistakes, businesses can take steps to avoid them, ensuring that their inventory tracking system is effective, efficient, and scalable.

Failing to Regularly Review and Update Inventory Levels

Failing to regularly review and update inventory levels is one of the most common inventory tracking mistakes that businesses can make. This can result in inaccurate or outdated inventory records, leading to stockouts, overstocking, and reduced operational efficiency. By regularly reviewing and updating inventory levels, businesses can ensure that their inventory tracking system is accurate and reliable, providing real-time visibility into inventory levels and enabling informed decision-making.Inventory Tracking Technology

There are several types of inventory tracking technology available, including barcode scanning, RFID tags, and inventory management software. These technologies can provide real-time visibility into inventory levels, enabling businesses to make informed decisions about production, shipping, and replenishment. By using inventory tracking technology, businesses can improve the accuracy and efficiency of their inventory tracking system, reducing costs and improving operational efficiency.

Barcode Scanning

Barcode scanning is a common type of inventory tracking technology that involves using barcode scanners to track the movement of goods within a warehouse or storage facility. Barcode scanning can provide real-time visibility into inventory levels, enabling businesses to make informed decisions about production, shipping, and replenishment. By using barcode scanning, businesses can improve the accuracy and efficiency of their inventory tracking system, reducing costs and improving operational efficiency.Inventory Tracking Image Gallery

What is inventory tracking?

+Inventory tracking involves monitoring and recording the movement of goods within a warehouse or storage facility.

Why is inventory tracking important?

+Inventory tracking is important because it helps businesses maintain accurate inventory levels, reduce stockouts and overstocking, and improve overall operational efficiency.

What are the benefits of inventory tracking?

+The benefits of inventory tracking include improved accuracy, reduced costs, and increased efficiency.

In conclusion, inventory tracking is a critical component of inventory management, providing real-time visibility into inventory levels and enabling businesses to make informed decisions about production, shipping, and replenishment. By implementing an effective inventory tracking system, businesses can improve the accuracy and efficiency of their inventory management processes, reducing costs and improving operational efficiency. Whether you are a small business or a large enterprise, inventory tracking is an essential tool for maintaining accurate inventory levels and improving overall business performance. We invite you to share your thoughts and experiences with inventory tracking in the comments section below, and to explore our other articles and resources on inventory management and related topics.