Effective inventory management is crucial for businesses of all sizes, as it directly impacts their bottom line. One of the key components of inventory management is inventory tracking, which involves monitoring and controlling the movement of goods within a warehouse or storage facility. In this article, we will explore the importance of inventory tracking and discuss five ways to implement an effective inventory tracking system.

Inventory tracking is essential for maintaining accurate inventory levels, reducing stockouts and overstocking, and improving overall supply chain efficiency. Without a reliable inventory tracking system, businesses may struggle to keep up with demand, leading to lost sales and revenue. Furthermore, inaccurate inventory levels can result in unnecessary purchases, wasted resources, and increased costs. By implementing an effective inventory tracking system, businesses can streamline their operations, reduce errors, and make informed decisions about their inventory.

Introduction to Inventory Tracking

Inventory tracking involves using various methods and technologies to monitor and control the movement of goods within a warehouse or storage facility. This can include tracking inventory levels, monitoring stock movements, and updating inventory records in real-time. By implementing an effective inventory tracking system, businesses can improve their inventory accuracy, reduce errors, and make informed decisions about their inventory.

Benefits of Inventory Tracking

The benefits of inventory tracking are numerous and can have a significant impact on a business's bottom line. Some of the key benefits of inventory tracking include:

* Improved inventory accuracy: Inventory tracking helps to ensure that inventory levels are accurate and up-to-date, reducing the risk of stockouts and overstocking.

* Reduced errors: Inventory tracking can help to reduce errors, such as mispicked or misplaced items, by providing a clear and accurate record of inventory movements.

* Improved supply chain efficiency: Inventory tracking can help to improve supply chain efficiency by providing real-time visibility into inventory levels and movements.

* Increased customer satisfaction: By ensuring that inventory levels are accurate and up-to-date, businesses can improve customer satisfaction by reducing the risk of stockouts and delayed shipments.

5 Ways to Implement Inventory Tracking

There are several ways to implement inventory tracking, depending on the size and complexity of the business. Here are five ways to implement inventory tracking:

1. **Barcode Scanning**: Barcode scanning is a popular method of inventory tracking that involves using a barcode scanner to track inventory movements. This method is quick and easy to implement and can be used in conjunction with other inventory tracking methods.

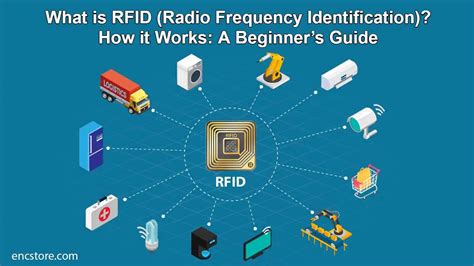

2. **Radio Frequency Identification (RFID)**: RFID is a technology that uses radio waves to track and identify inventory items. This method is more expensive than barcode scanning but provides real-time visibility into inventory levels and movements.

3. **Inventory Management Software**: Inventory management software is a type of software that is designed to help businesses manage their inventory. This software can be used to track inventory levels, monitor stock movements, and update inventory records in real-time.

4. **Manual Inventory Tracking**: Manual inventory tracking involves using a manual system, such as a spreadsheet or a paper-based system, to track inventory movements. This method is simple and inexpensive but can be time-consuming and prone to errors.

5. **Automated Inventory Tracking**: Automated inventory tracking involves using automated systems, such as robots or automated storage and retrieval systems, to track inventory movements. This method is more expensive than other methods but provides real-time visibility into inventory levels and movements.

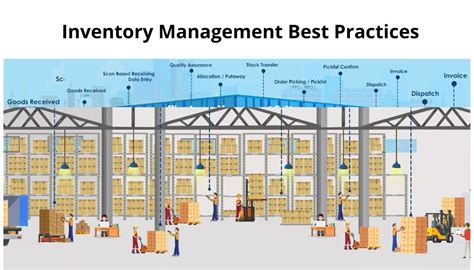

Best Practices for Inventory Tracking

To get the most out of an inventory tracking system, businesses should follow best practices, such as:

* **Implementing a robust inventory tracking system**: A robust inventory tracking system should be able to track inventory levels, monitor stock movements, and update inventory records in real-time.

* **Providing training to employees**: Employees should be trained on how to use the inventory tracking system and how to perform inventory tracking tasks.

* **Regularly reviewing and updating inventory records**: Inventory records should be regularly reviewed and updated to ensure that they are accurate and up-to-date.

* **Using data analytics to inform inventory decisions**: Data analytics can be used to inform inventory decisions, such as determining optimal inventory levels and identifying trends in inventory movements.

Common Challenges in Inventory Tracking

Despite the benefits of inventory tracking, there are common challenges that businesses may face when implementing an inventory tracking system. Some of the common challenges include:

* **Implementing a new system**: Implementing a new inventory tracking system can be time-consuming and may require significant changes to business processes.

* **Training employees**: Employees may require training on how to use the new inventory tracking system, which can be time-consuming and may require significant resources.

* **Integrating with existing systems**: The new inventory tracking system may need to be integrated with existing systems, such as enterprise resource planning (ERP) systems or customer relationship management (CRM) systems.

* **Ensuring data accuracy**: Ensuring that inventory data is accurate and up-to-date can be a challenge, particularly if the business has a large and complex inventory.

Gallery of Inventory Tracking

Inventory Tracking Image Gallery

Frequently Asked Questions

What is inventory tracking?

+

Inventory tracking is the process of monitoring and controlling the movement of goods within a warehouse or storage facility.

Why is inventory tracking important?

+

Inventory tracking is important because it helps businesses maintain accurate inventory levels, reduce stockouts and overstocking, and improve overall supply chain efficiency.

What are the benefits of inventory tracking?

+

The benefits of inventory tracking include improved inventory accuracy, reduced errors, improved supply chain efficiency, and increased customer satisfaction.

How can I implement an inventory tracking system?

+

There are several ways to implement an inventory tracking system, including using barcode scanning, radio frequency identification (RFID), inventory management software, manual inventory tracking, and automated inventory tracking.

What are the common challenges in inventory tracking?

+

The common challenges in inventory tracking include implementing a new system, training employees, integrating with existing systems, and ensuring data accuracy.

In conclusion, inventory tracking is a crucial component of inventory management that can help businesses maintain accurate inventory levels, reduce stockouts and overstocking, and improve overall supply chain efficiency. By implementing an effective inventory tracking system, businesses can streamline their operations, reduce errors, and make informed decisions about their inventory. We encourage readers to share their experiences and tips on implementing inventory tracking systems in the comments section below. Additionally, we invite readers to explore our other articles on inventory management and supply chain optimization to learn more about how to improve their business operations.