Intro

Master welding symbols with 5 expert tips, covering weld types, joint designs, and fabrication techniques, to improve welding processes and blueprint interpretations.

Welding symbols are a crucial part of engineering and construction, as they provide a standardized way to communicate welding requirements and specifications. Understanding these symbols is essential for ensuring that welds are executed correctly and safely. In this article, we will delve into the world of weld symbols, exploring their importance, and providing five valuable tips for working with them.

The use of weld symbols simplifies the communication process between designers, engineers, and welders. These symbols convey detailed information about the type of weld, its size, and other critical specifications. Without a standardized system of symbols, there would be a significant risk of misinterpretation, leading to faulty welds that could compromise the integrity of structures and machinery. As such, it's paramount for professionals in the field to be well-versed in reading and interpreting weld symbols accurately.

Weld symbols are not just limited to indicating the presence of a weld; they also specify the technique, the preparation of the pieces to be welded, and any additional treatments required after welding. This comprehensive approach ensures that every aspect of the welding process is considered and executed according to the design specifications. Given the complexity and the critical nature of welding in construction and manufacturing, mastering weld symbols is an indispensable skill.

Introduction to Weld Symbols

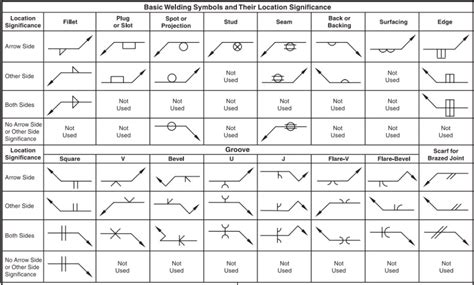

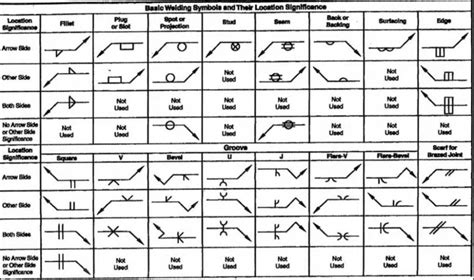

The introduction to weld symbols begins with understanding the basic elements that make up these symbols. The American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME) provide standards for weld symbols, ensuring consistency across different projects and industries. These standards cover the shape, size, and location of welds, as well as the process used to create them. By familiarizing oneself with these standards, one can better navigate the complex world of weld symbols.

Understanding Weld Symbol Components

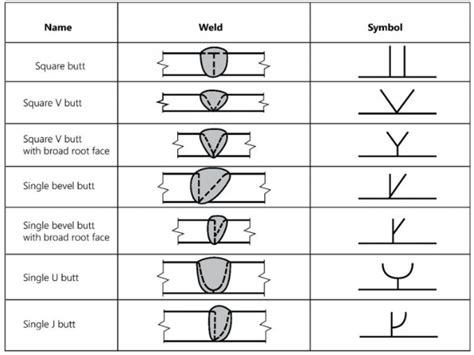

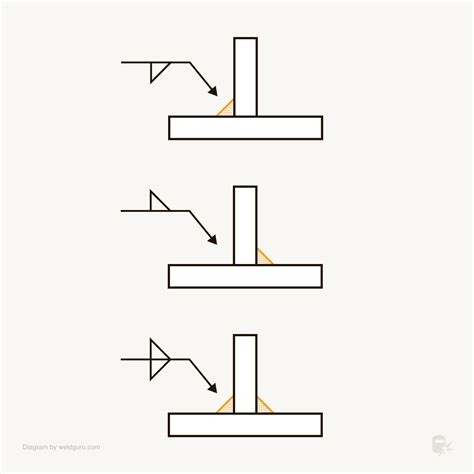

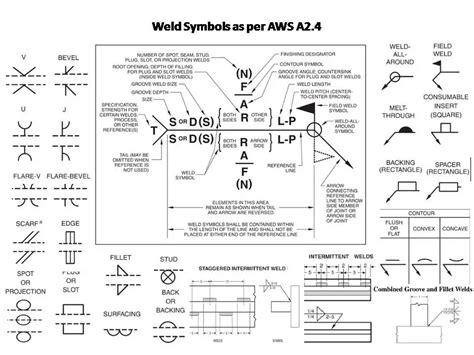

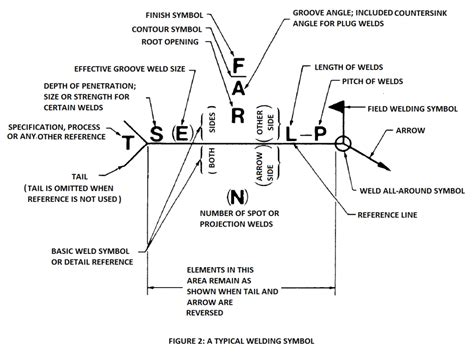

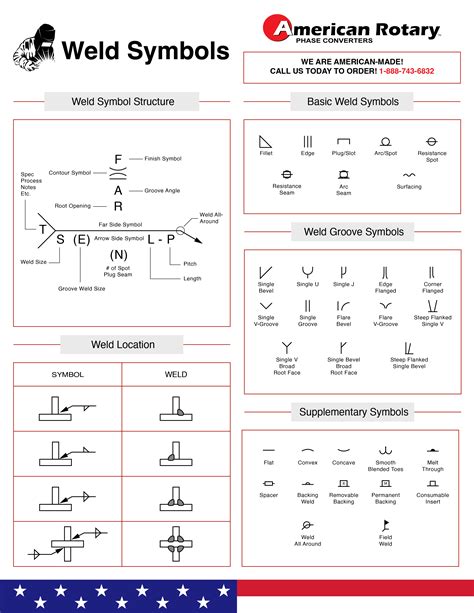

Each weld symbol is composed of several components, each conveying specific information. The tail of the symbol, for instance, may contain additional specifications such as the welding process, the filler metal to be used, or any special conditions required for the weld. The arrow side of the symbol indicates the side of the joint where the weld is to be made, while the other side (if not specified) implies the weld is to be made on the opposite side of the joint. Understanding these components is crucial for accurate interpretation and execution of welding tasks.

Key Components of Weld Symbols

- Reference Line: The basis of the weld symbol, from which all other elements are drawn.

- Arrow: Points to the joint where the weld is to be made.

- Tail: May contain additional information such as process, filler metal, or special conditions.

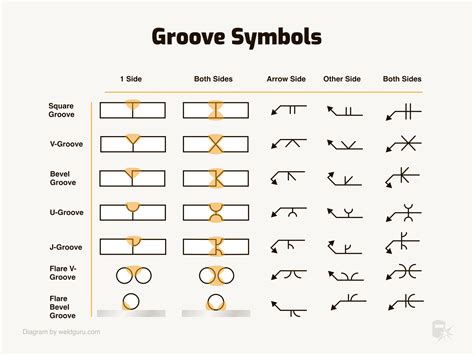

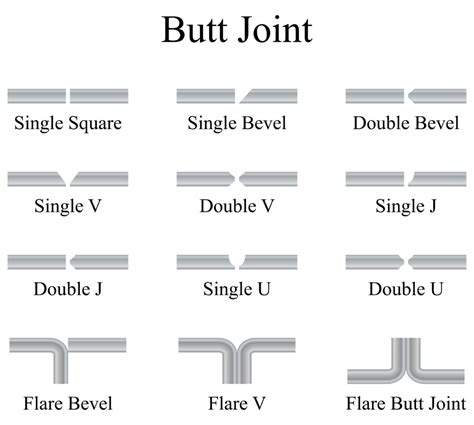

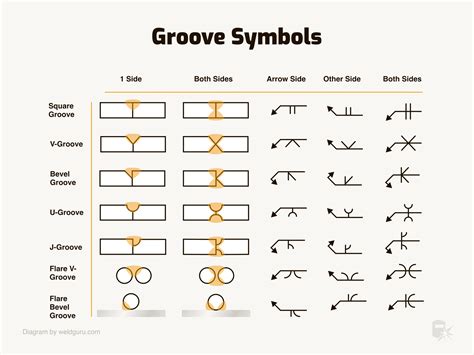

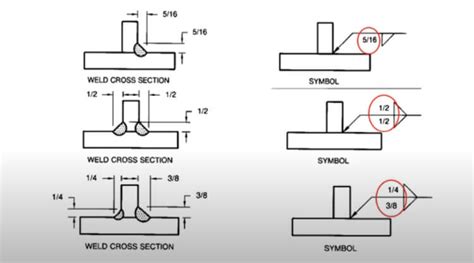

- Weld Symbol: Indicates the type of weld required (e.g., fillet, groove, flare-bevel).

- Dimensions and Contours: Specify the size and shape of the weld.

Five Weld Symbol Tips

- Master the Basics: Start by thoroughly understanding the basic components of weld symbols. This foundation is essential for interpreting more complex symbols and specifications.

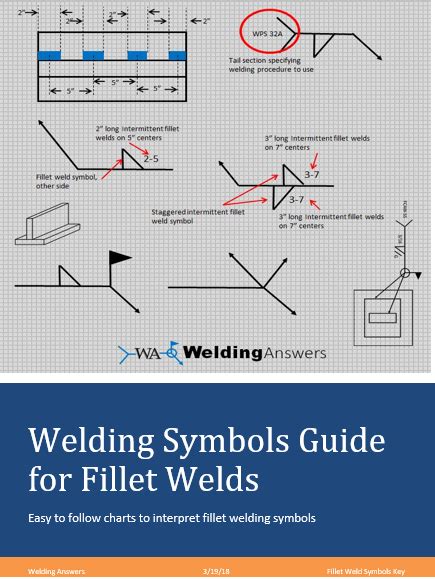

- Practice Interpretation: The best way to become proficient in reading weld symbols is through practice. Use sample drawings and symbols to test your understanding and identify areas for improvement.

- Stay Updated with Standards: Welding standards and symbol conventions can evolve. Stay informed about updates from organizations like AWS and ASME to ensure your knowledge remains current.

- Use Reference Materials: Keep a reference guide handy for quick lookups. This could be a physical manual or a digital resource, depending on what works best for your workflow.

- Apply Symbols in Context: Understanding how weld symbols are applied in real-world scenarios is crucial. Look at actual blueprints and specifications to see how symbols are used to communicate welding requirements in different contexts.

Applying Weld Symbols in Real-World Scenarios

- Construction Projects: Weld symbols are critical in construction for specifying welds in building frames, bridges, and other structures.

- Manufacturing: In manufacturing, weld symbols ensure that parts are assembled correctly, whether it's for machinery, vehicles, or consumer products.

- Shipbuilding: The precise application of weld symbols is vital in shipbuilding, where the integrity of welds can affect the safety and performance of vessels.

Common Mistakes to Avoid

When working with weld symbols, there are several common mistakes to be aware of and avoid. One of the most critical errors is misinterpreting the symbol itself, which can lead to incorrect weld types or sizes. Another mistake is overlooking the specifications in the tail of the symbol, which can result in using the wrong welding process or filler metal. Ensuring that all aspects of the weld symbol are correctly understood and applied is essential for avoiding these mistakes.

Best Practices for Accuracy

- Double-Check Symbols: Always verify the interpretation of weld symbols against reference materials.

- Use Standardized Symbols: Ensure that all symbols used are in accordance with recognized standards.

- Communicate Clearly: When specifying welds, communicate clearly and unambiguously to avoid misunderstandings.

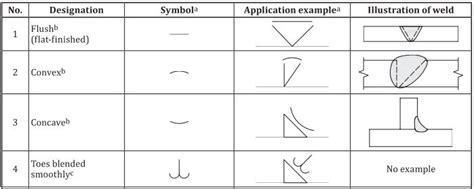

Gallery of Welding Symbols

Welding Symbols Gallery

What is the purpose of weld symbols in engineering and construction?

+Weld symbols provide a standardized way to communicate welding requirements and specifications, ensuring that welds are executed correctly and safely.

How do I become proficient in reading weld symbols?

+Becoming proficient in reading weld symbols involves mastering the basics, practicing interpretation, staying updated with standards, using reference materials, and applying symbols in real-world contexts.

What are some common mistakes to avoid when working with weld symbols?

+Common mistakes include misinterpreting the symbol, overlooking specifications in the tail, and not using standardized symbols. Best practices for accuracy include double-checking symbols, using standardized symbols, and communicating clearly.

In conclusion, weld symbols are a vital component of the welding process, providing essential information for the execution of safe and effective welds. By understanding the components of weld symbols, avoiding common mistakes, and following best practices, professionals in the field can ensure that their work meets the highest standards of quality and safety. Whether you're a seasoned welder or just starting out, mastering weld symbols is an indispensable part of your toolkit. Share your thoughts on the importance of weld symbols in the comments below, and don't forget to share this article with anyone who might find it useful. Together, we can promote better understanding and application of weld symbols in our industries.