Intro

Boost efficiency with 5 inventory tips, including stock management, supply chain optimization, and warehouse organization, to improve logistics and reduce costs, using effective inventory control and tracking systems for better business outcomes.

Effective inventory management is crucial for businesses across various industries, as it directly impacts their bottom line, customer satisfaction, and overall operational efficiency. Managing inventory well can be the difference between a business thriving and one that struggles to stay afloat. In this article, we will delve into the importance of inventory management, explore some common challenges, and most importantly, provide actionable tips to help businesses optimize their inventory practices.

Inventory management involves tracking and controlling the goods, products, or materials a company has in stock. It encompasses everything from raw materials to finished goods, and even the goods that are in transit or being stored in warehouses. Effective inventory management ensures that a business has the right products in the right quantities, at the right time, and at the right place. This balance is critical because having too much inventory can lead to unnecessary expenses due to storage and maintenance costs, while having too little can result in lost sales and disappointed customers.

The challenges in inventory management are multifaceted. For instance, businesses must contend with forecasting demand accurately, managing lead times, dealing with supply chain disruptions, and optimizing storage space. Moreover, with the rise of e-commerce and omnichannel retailing, businesses now face the additional complexity of managing inventory across multiple sales channels and fulfillment points. Despite these challenges, there are strategies and technologies available that can significantly improve inventory management practices.

Understanding Inventory Management Basics

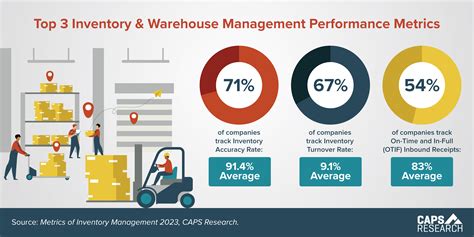

Before diving into advanced inventory management strategies, it's essential to understand the basics. This includes knowing the different types of inventory, such as raw materials, work-in-progress, and finished goods. Businesses should also be familiar with key inventory metrics, including inventory turnover, days inventory outstanding (DIO), and fill rates. Understanding these fundamentals provides a solid foundation for more advanced inventory management practices.

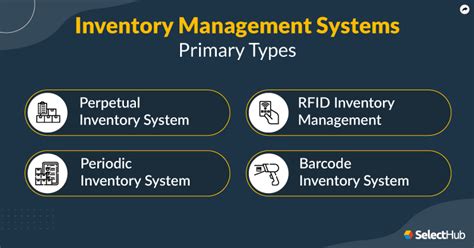

Implementing Inventory Management Systems

One of the most effective ways to improve inventory management is by implementing an inventory management system. These systems use software to track, manage, and analyze inventory levels, orders, and sales. They can automate many tasks, provide real-time data, and offer insights that help in making informed decisions. When choosing an inventory management system, businesses should consider factors such as scalability, integration with existing systems, and the level of support provided by the vendor.

Inventory Forecasting and Demand Planning

Accurate forecasting and demand planning are critical components of effective inventory management. By analyzing historical sales data, seasonal trends, and other factors, businesses can predict future demand and adjust their inventory levels accordingly. This helps in avoiding overstocking and understocking, reducing waste, and ensuring that popular items are always available. Advanced forecasting techniques, such as machine learning algorithms, can further enhance the accuracy of demand predictions.

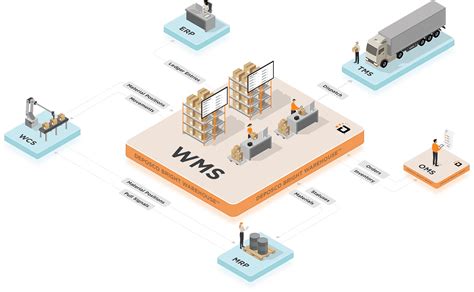

Optimizing Warehouse Operations

The efficiency of warehouse operations directly impacts inventory management. Optimizing warehouse layout, implementing efficient picking and packing processes, and utilizing warehouse management systems can significantly reduce costs and improve delivery times. Businesses should also consider adopting practices such as just-in-time (JIT) inventory and drop shipping to minimize inventory holdings and maximize the use of space.

Monitoring and Analyzing Inventory Performance

Continuous monitoring and analysis of inventory performance are essential for identifying areas of improvement and measuring the effectiveness of inventory management strategies. Key performance indicators (KPIs) such as inventory turnover, fill rates, and order fulfillment rates should be regularly reviewed. Analyzing these metrics helps businesses understand their inventory dynamics better, enabling them to make data-driven decisions that optimize their inventory levels and improve customer satisfaction.

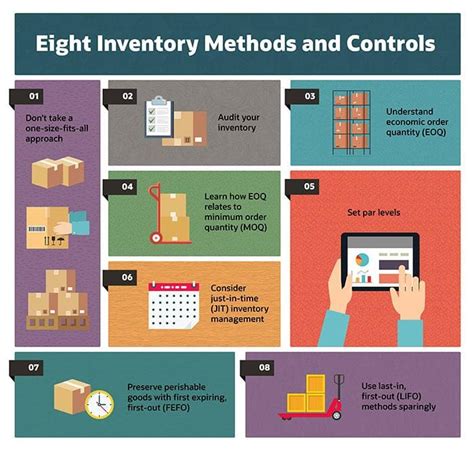

Here are five inventory tips that businesses can implement to improve their inventory management:

-

Conduct Regular Inventory Audits: Regular audits help ensure that the physical count of inventory matches the records. This process can identify discrepancies, reduce errors, and prevent inventory shrinkage.

-

Implement a First-In, First-Out (FIFO) Policy: This policy ensures that older inventory is sold or used before newer inventory, reducing the risk of inventory becoming obsolete or expired.

-

Use Inventory Management Software: Inventory management software automates many inventory-related tasks, provides real-time inventory levels, and offers insights into inventory trends and patterns.

-

Optimize Inventory Levels Based on Demand: Analyzing historical sales data and forecasting future demand helps businesses adjust their inventory levels accordingly, reducing the likelihood of overstocking or understocking.

-

Consider Outsourcing Inventory Management: For some businesses, especially small and medium-sized enterprises, outsourcing inventory management to a third-party logistics provider can be a cost-effective and efficient solution, allowing them to focus on their core operations.

Inventory Management Image Gallery

What is the importance of inventory management in business?

+Inventory management is crucial for businesses as it helps in maintaining the right stock levels, reducing costs, and improving customer satisfaction. Effective inventory management ensures that businesses have the products they need when they need them, without overstocking or understocking.

How can businesses implement effective inventory management systems?

+Businesses can implement effective inventory management systems by first understanding their inventory needs, selecting the right inventory management software, and ensuring that all stakeholders are trained on how to use the system. Regular monitoring and analysis of inventory performance are also key to making adjustments and improvements.

What are some common challenges in inventory management, and how can they be overcome?

+Common challenges in inventory management include forecasting demand accurately, managing supply chain disruptions, and optimizing warehouse operations. These challenges can be overcome by adopting advanced forecasting techniques, diversifying supply chains, and implementing efficient warehouse management practices. Technology, such as inventory management software and automation, can also play a significant role in mitigating these challenges.

In conclusion, effective inventory management is a cornerstone of successful businesses. By understanding the basics of inventory management, implementing inventory management systems, forecasting demand accurately, optimizing warehouse operations, and continuously monitoring and analyzing inventory performance, businesses can significantly improve their inventory practices. Whether a business is small, medium, or large, adopting these strategies can lead to reduced costs, improved customer satisfaction, and ultimately, increased profitability. We invite our readers to share their experiences and tips on inventory management, and we look forward to continuing the conversation on this critical aspect of business operations.