Intro

Discover 5 ways limited labels impact business, including label management, supply chain optimization, and inventory control, to improve labeling efficiency and reduce errors with effective label solutions and strategies.

The world of organization and labeling has seen a significant surge in recent years, with many individuals and businesses seeking to streamline their processes and improve productivity. One aspect that has gained considerable attention is the use of limited labels. These labels, designed to be concise and efficient, have become a staple in various industries, from retail and manufacturing to healthcare and education. In this article, we will delve into the concept of limited labels, exploring their benefits, applications, and best practices for implementation.

Limited labels are essentially a type of labeling system that restricts the amount of information displayed on a label. This approach is based on the principle that less is often more, and that by limiting the information on a label, it becomes easier to read, understand, and act upon. The idea behind limited labels is to provide only the most essential information, eliminating clutter and reducing visual noise. By doing so, individuals can quickly identify what they need to know, making it an effective tool for improving efficiency and reducing errors.

The importance of limited labels cannot be overstated. In today's fast-paced world, where time is of the essence, having a labeling system that is clear, concise, and easy to understand is crucial. Limited labels have been shown to improve productivity, reduce mistakes, and enhance overall performance. Moreover, they have become an essential component in various industries, where accurate and efficient labeling is critical. For instance, in healthcare, limited labels are used to identify medical supplies, equipment, and patient records, ensuring that medical professionals can quickly access the information they need to provide quality care.

Benefits of Limited Labels

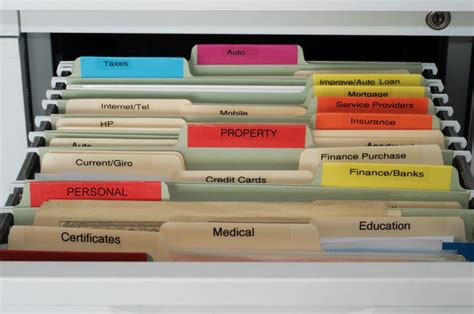

Another significant benefit of limited labels is their ability to improve organization and streamline processes. By using a standardized labeling system, businesses and individuals can create a more efficient and productive environment. Limited labels can be used to categorize and prioritize tasks, identify important documents and files, and even track inventory and supplies. This, in turn, can lead to significant cost savings, as well as improved customer satisfaction and loyalty.

Applications of Limited Labels

Limited labels have a wide range of applications across various industries. In retail, they are used to label products, prices, and inventory levels, making it easier for customers to find what they need and for staff to manage stock levels. In manufacturing, limited labels are used to identify components, track production schedules, and ensure quality control. In healthcare, they are used to label medical supplies, equipment, and patient records, ensuring that medical professionals can quickly access the information they need to provide quality care.Best Practices for Implementing Limited Labels

Another critical aspect of implementing limited labels is to ensure consistency across the organization. This can be achieved by developing a standardized labeling system and providing training to staff on its use. It is also essential to regularly review and update the labeling system to ensure that it remains effective and efficient.

Common Mistakes to Avoid

When implementing limited labels, there are several common mistakes to avoid. One of the most significant errors is to include too much information on the label, which can lead to clutter and confusion. Another mistake is to use a font or color scheme that is difficult to read, which can reduce the effectiveness of the labeling system. Additionally, failing to regularly review and update the labeling system can lead to inaccuracies and inefficiencies.Case Studies and Examples

Future Developments and Trends

The use of limited labels is expected to continue to grow and evolve in the coming years. One of the most significant trends is the increasing use of technology, such as barcode scanning and RFID, to improve the efficiency and accuracy of labeling systems. Another trend is the development of more sustainable and environmentally friendly labeling options, such as biodegradable labels and recyclable materials.Conclusion and Recommendations

We recommend that businesses and individuals consider implementing limited labels as part of their organizational strategy. By doing so, they can improve efficiency, reduce errors, and enhance overall performance. Additionally, we recommend regularly reviewing and updating the labeling system to ensure that it remains effective and efficient.

Final Thoughts and Next Steps

As next steps, we recommend that readers take the following actions:

- Determine what information is essential and what can be omitted from labels

- Choose the right labeling system, including the type of label, font, and color scheme

- Ensure consistency across the organization by developing a standardized labeling system and providing training to staff

- Regularly review and update the labeling system to ensure that it remains effective and efficient

Image Gallery of Limited Labels

What are limited labels?

+Limited labels are a type of labeling system that restricts the amount of information displayed on a label, providing only the most essential information.

What are the benefits of limited labels?

+The benefits of limited labels include improved readability, increased efficiency, and enhanced accuracy, as well as reduced errors and improved overall performance.

How can I implement limited labels in my organization?

+To implement limited labels, determine what information is essential, choose the right labeling system, and ensure consistency across the organization. Regularly review and update the labeling system to ensure it remains effective and efficient.

What are some common mistakes to avoid when implementing limited labels?

+Common mistakes to avoid include including too much information on the label, using a font or color scheme that is difficult to read, and failing to regularly review and update the labeling system.

How can I ensure the effectiveness of limited labels in my organization?

+To ensure the effectiveness of limited labels, regularly review and update the labeling system, provide training to staff, and monitor the impact of the labeling system on efficiency and accuracy.

We hope this article has provided valuable insights into the concept of limited labels and their applications. We encourage readers to share their thoughts and experiences with limited labels in the comments section below. Additionally, we invite readers to share this article with others who may benefit from the information. By working together, we can improve efficiency, reduce errors, and enhance overall performance in various industries and aspects of life.