Intro

Boost efficiency with 5 Ways Warehouse Management, optimizing inventory control, supply chain logistics, and distribution operations, using warehouse automation and inventory management systems.

The importance of efficient warehouse management cannot be overstated, as it plays a critical role in the success of any business that deals with physical products. A well-managed warehouse enables companies to reduce costs, improve customer satisfaction, and gain a competitive edge in the market. With the rise of e-commerce and the increasing demand for fast and reliable shipping, warehouse management has become more complex and challenging. In this article, we will explore the different aspects of warehouse management and provide insights into how businesses can optimize their warehouse operations.

Effective warehouse management is crucial for businesses that want to stay ahead of the competition. It involves a range of activities, including inventory management, order fulfillment, and shipping. A well-managed warehouse ensures that products are stored and handled properly, reducing the risk of damage and loss. It also enables businesses to respond quickly to changes in demand, ensuring that customers receive their orders on time. In addition, a efficient warehouse management system can help businesses to reduce their costs, improve their productivity, and increase their revenue.

The benefits of efficient warehouse management are numerous, and businesses that invest in optimizing their warehouse operations can expect to see significant improvements in their overall performance. Some of the key benefits of efficient warehouse management include improved inventory accuracy, reduced labor costs, and increased customer satisfaction. By implementing a warehouse management system, businesses can also improve their supply chain visibility, enabling them to make informed decisions about their inventory and shipping operations. Furthermore, a well-managed warehouse can help businesses to reduce their environmental impact, by minimizing waste and reducing energy consumption.

Introduction to Warehouse Management

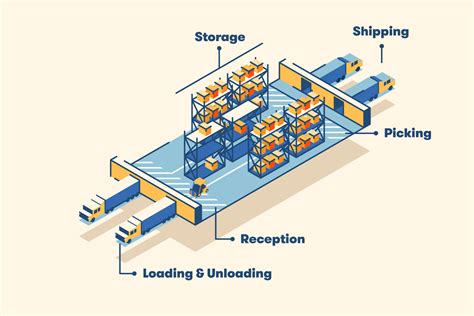

Warehouse management refers to the process of organizing and controlling the movement of goods within a warehouse. It involves a range of activities, including receiving, storing, and shipping products. Effective warehouse management requires a combination of technology, processes, and people, and is critical to the success of any business that deals with physical products. A well-managed warehouse enables businesses to reduce costs, improve customer satisfaction, and gain a competitive edge in the market. In this section, we will explore the different aspects of warehouse management and provide insights into how businesses can optimize their warehouse operations.

Key Components of Warehouse Management

The key components of warehouse management include inventory management, order fulfillment, and shipping. Inventory management involves tracking and managing the movement of goods within the warehouse, ensuring that products are stored and handled properly. Order fulfillment involves processing and preparing customer orders for shipping, while shipping involves transporting products from the warehouse to the customer. Other key components of warehouse management include warehouse design, layout, and equipment, as well as labor management and training.Benefits of Efficient Warehouse Management

The benefits of efficient warehouse management are numerous, and businesses that invest in optimizing their warehouse operations can expect to see significant improvements in their overall performance. Some of the key benefits of efficient warehouse management include improved inventory accuracy, reduced labor costs, and increased customer satisfaction. By implementing a warehouse management system, businesses can also improve their supply chain visibility, enabling them to make informed decisions about their inventory and shipping operations. Furthermore, a well-managed warehouse can help businesses to reduce their environmental impact, by minimizing waste and reducing energy consumption.

Improved Inventory Accuracy

One of the key benefits of efficient warehouse management is improved inventory accuracy. A well-managed warehouse enables businesses to track and manage their inventory in real-time, reducing the risk of errors and discrepancies. This can help businesses to avoid stockouts and overstocking, ensuring that they have the right products in stock to meet customer demand. Improved inventory accuracy can also help businesses to reduce their labor costs, by minimizing the need for manual inventory counts and reducing the risk of inventory-related errors.Warehouse Management Best Practices

There are several best practices that businesses can follow to optimize their warehouse operations. Some of the key best practices include implementing a warehouse management system, optimizing warehouse layout and design, and investing in employee training and development. Businesses can also benefit from implementing lean principles and continuous improvement methodologies, such as Six Sigma and Kaizen. By following these best practices, businesses can improve their warehouse efficiency, reduce costs, and increase customer satisfaction.

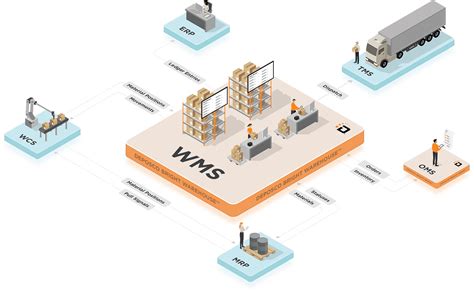

Implementing a Warehouse Management System

A warehouse management system (WMS) is a software application that enables businesses to manage and control their warehouse operations. A WMS can help businesses to improve their inventory accuracy, reduce labor costs, and increase customer satisfaction. Some of the key features of a WMS include inventory tracking and management, order fulfillment and shipping, and reporting and analytics. By implementing a WMS, businesses can gain real-time visibility into their warehouse operations, enabling them to make informed decisions about their inventory and shipping operations.Warehouse Management Technologies

There are several technologies that businesses can use to optimize their warehouse operations. Some of the key technologies include barcode scanning and RFID, automated storage and retrieval systems (AS/RS), and warehouse management software. Businesses can also benefit from implementing robotics and automation, such as robotic pickers and packers. By leveraging these technologies, businesses can improve their warehouse efficiency, reduce costs, and increase customer satisfaction.

Barcode Scanning and RFID

Barcode scanning and RFID are two technologies that can help businesses to improve their inventory accuracy and reduce labor costs. Barcode scanning involves using a barcode scanner to track and manage inventory, while RFID involves using radio frequency identification tags to track and manage inventory. Both technologies can help businesses to improve their inventory accuracy, reduce labor costs, and increase customer satisfaction.Warehouse Management Challenges

There are several challenges that businesses may face when managing their warehouse operations. Some of the key challenges include inventory management, labor management, and supply chain visibility. Businesses may also face challenges related to warehouse design and layout, as well as equipment and technology. By understanding these challenges, businesses can develop strategies to overcome them and optimize their warehouse operations.

Inventory Management Challenges

Inventory management is one of the key challenges that businesses may face when managing their warehouse operations. Inventory management involves tracking and managing the movement of goods within the warehouse, ensuring that products are stored and handled properly. Businesses may face challenges related to inventory accuracy, stockouts, and overstocking. By implementing a warehouse management system and optimizing their inventory management processes, businesses can overcome these challenges and improve their overall performance.Future of Warehouse Management

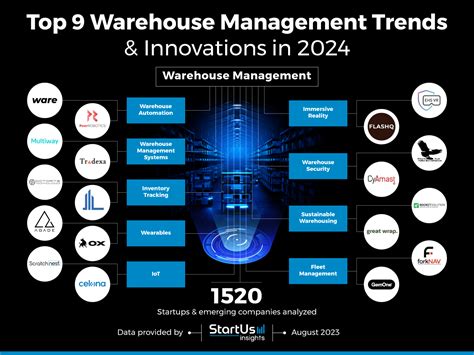

The future of warehouse management is likely to be shaped by several trends and technologies, including the Internet of Things (IoT), artificial intelligence (AI), and robotics. Businesses can expect to see increased use of automation and robotics in warehouses, as well as greater adoption of cloud-based warehouse management systems. By leveraging these trends and technologies, businesses can improve their warehouse efficiency, reduce costs, and increase customer satisfaction.

Internet of Things (IoT)

The Internet of Things (IoT) is a network of physical devices, vehicles, and other items that are embedded with sensors, software, and connectivity, allowing them to collect and exchange data. In the context of warehouse management, IoT can help businesses to improve their inventory accuracy, reduce labor costs, and increase customer satisfaction. By leveraging IoT technologies, such as sensors and RFID tags, businesses can gain real-time visibility into their warehouse operations, enabling them to make informed decisions about their inventory and shipping operations.Warehouse Management Image Gallery

What is warehouse management?

+Warehouse management refers to the process of organizing and controlling the movement of goods within a warehouse. It involves a range of activities, including receiving, storing, and shipping products.

What are the benefits of efficient warehouse management?

+The benefits of efficient warehouse management include improved inventory accuracy, reduced labor costs, and increased customer satisfaction. By implementing a warehouse management system, businesses can also improve their supply chain visibility, enabling them to make informed decisions about their inventory and shipping operations.

What are some common warehouse management challenges?

+Some common warehouse management challenges include inventory management, labor management, and supply chain visibility. Businesses may also face challenges related to warehouse design and layout, as well as equipment and technology.

What is the future of warehouse management?

+The future of warehouse management is likely to be shaped by several trends and technologies, including the Internet of Things (IoT), artificial intelligence (AI), and robotics. Businesses can expect to see increased use of automation and robotics in warehouses, as well as greater adoption of cloud-based warehouse management systems.

How can businesses optimize their warehouse operations?

+Businesses can optimize their warehouse operations by implementing a warehouse management system, optimizing their warehouse layout and design, and investing in employee training and development. They can also benefit from implementing lean principles and continuous improvement methodologies, such as Six Sigma and Kaizen.

In final thoughts, efficient warehouse management is critical to the success of any business that deals with physical products. By implementing a warehouse management system, optimizing warehouse layout and design, and investing in employee training and development, businesses can improve their warehouse efficiency, reduce costs, and increase customer satisfaction. We encourage readers to share their thoughts and experiences on warehouse management, and to explore the resources and tools available to help them optimize their warehouse operations. Whether you are a seasoned logistics professional or just starting out, we hope that this article has provided you with valuable insights and practical advice on how to improve your warehouse management skills.